Fabricating shape-shifting objects with hobbyist 3-D printers

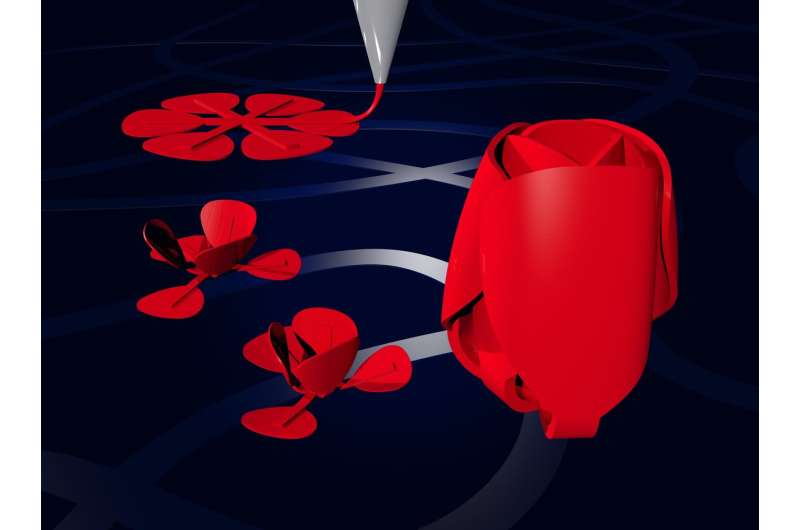

Researchers at TU Delft have combined origami techniques and 3-D printing to create flat structures that can fold themselves into 3-D structures like tulips. The structures self-fold according to a pre-planned sequence, with some parts folding sooner than others. Usually, expensive printers and special materials are needed to fabricate such objects. But the TU Delft scientists have created a new technique that requires only a common 3-D printer and ubiquitous material. Among other applications, their research has the potential to greatly improve bone implants.

Amir Zadpoor of TU Delft and his team combined traditional Japanese paper folding art with the more novel technology of 3-D printing in order to create constructs that can self-roll, self-twist, self-wrinkle and self-fold into a variety of 3-D structures. In 2016, the researchers demonstrated several self-folding objects. "But there were still serious challenges we needed to address," says Zadpoor.

Manual labour is usually involved in the fabrication of shape-shifting devices, and the material researchers normally use is neither ubiquitous nor cheap. But in this recent project, Zadpoor's team used an Ultimaker, which is one of the most popular 3-D printers, and PLA, the most common printing material available. "At about €17 per kilo, it's dirt cheap," says Zadpoor. "Nevertheless, we created some of the most complex shape-shifting ever reported with it." The process is also fully automated and requires no manual labour whatsoever.

The team's shape-shifting objects self-fold according to a pre-planned sequence. "If the goal is to create complex shapes, some parts should fold sooner than others," Zadpoor explains. "Therefore, we needed to program time delays into the material. This is called sequential shape-shifting."

The way in which Zadpoor's team managed to do this was by simultaneously printing and stretching the material in certain spots. "The stretching is stored inside the material as a memory," says Ph.D. researcher Teunis van Manen. "When heated up, the memory is released and the material returns to its original state." By also alternating the thickness and the alignment of the filaments in the material, the researchers succeeded in creating 2-D-structures that shape-shift sequentially.

Long-lasting bone implants

The combined approach of origami and 3-D printing is an important step in the development of better bone implants. First, the technique makes it possible to create prosthetics with a porous interior. This will allow a patient's own stem cells to move into the structure of the implant and attach themselves to the interior surface area, instead of just coating the exterior. The end result will be a stronger, more durable implant.

Secondly, with this technique, nanopatterns that guide cell growth can be crafted on the surface of the implant. The researchers call these "instructive surfaces," because they apply certain forces to the stem cells, prompting them to develop into specific cells. Ph.D. researcher Shahram Janbaz says, "A pillar shape, for instance, may encourage stem cells to become bone cells." It is impossible to create such instructive surfaces on the inside of a 3-D structure. Zadpoor says, "This is why we decided we needed to start from a flat surface."

Self-folding furniture

While bone implants may be the most obvious application for their research, the scientists believe that the shape-shifting technology could also lead to other developments in due time. "Printed electronics, for instance, can also benefit from our research," says Zadpoor. "By using this technique, it may be possible to incorporate printed, 2-D-electronics into a 3-D shape.

Zadpoor also sees a future in which you can buy a 2-D-sheet at IKEA that, after you unpack it and apply a certain stimulus, turns into a ready-to-use piece of furniture. "Shape-shifting could definitely turn many of our existing 2-D worlds into 3-D worlds," he says. "We are already being contacted by people who are interested in working with it."

More information: Teunis van Manen et al. Programming 2D/3D shape-shifting with hobbyist 3D printers, Mater. Horiz. (2017). DOI: 10.1039/C7MH00269F

Provided by Delft University of Technology