Scientists make atoms-thick Post-It notes for solar cells and circuits

Over the past half-century, scientists have shaved silicon films down to just a wisp of atoms in pursuit of smaller, faster electronics. For the next set of breakthroughs, though, they'll need novel ways to build even tinier and more powerful devices.

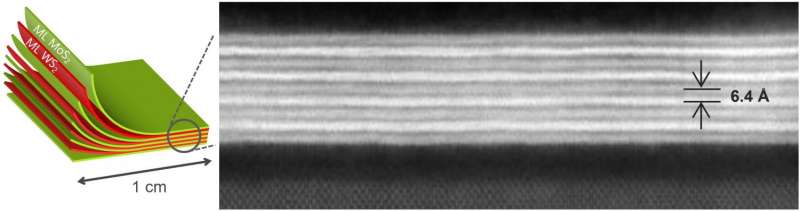

A study led by UChicago researchers, published Sept. 20 in Nature, describes an innovative method to make stacks of semiconductors just a few atoms thick. The technique offers scientists and engineers a simple, cost-effective method to make thin, uniform layers of these materials, which could expand capabilities for devices from solar cells to cell phones.

Stacking thin layers of materials offers a range of possibilities for making electronic devices with unique properties. But manufacturing such films is a delicate process, with little room for error.

"The scale of the problem we're looking at is, imagine trying to lay down a flat sheet of plastic wrap the size of Chicago without getting any air bubbles in it," said Jiwoong Park, a UChicago professor with the Department of Chemistry, the Institute for Molecular Engineering and the James Franck Institute, who led the study. "When the material itself is just atoms thick, every little stray atom is a problem."

Today, these layers are "grown" instead of stacking them on top of one another. But that means the bottom layers have to be subjected to harsh growth conditions such as high temperatures while the new ones are added—a process that limits the materials with which to make them.

Park's team instead made the films individually. Then they put them into a vacuum, peeled them off and stuck them to one another, like Post-It notes. This allowed the scientists to make films that were connected with weak bonds instead of stronger covalent bonds—interfering less with the perfect surfaces between the layers.

"The films, vertically controlled at the atomic-level, are exceptionally high-quality over entire wafers," said Kibum Kang, a postdoctoral associate who was the first author of the study.

Kan-Heng Lee, a graduate student and co-first author of the study, then tested the films' electrical properties by making them into devices and showed that their functions can be designed on the atomic scale, which could allow them to serve as the essential ingredient for future computer chips.

The method opens up a myriad of possibilities for such films. They can be made on top of water or plastics; they can be made to detach by dipping them into water; and they can be carved or patterned with an ion beam. Researchers are exploring the full range of what can be done with the method, which they said is simple and cost-effective.

"We expect this new method to accelerate the discovery of novel materials, as well as enabling large-scale manufacturing," Park said.

More information: "Layer-by-layer assembly of two-dimensional materials into wafer-scale heterostructures," Kang et. al, Nature, Sept. 20. DOI: 10.1038/nature23905

Journal information: Nature

Provided by University of Chicago