Controlling the stiffness of a material at the nanoscale

Using a needle far thinner than a human hair, scientists revealed how to control mechanical stiffness in a promising material. The team applied an electric field with a nano-sized needle to cause a reversible change in the arrangement of the atoms in the material. This change is a phase transition. The team reconfigured the atomic force microscope they used to measure the resulting change in the mechanical properties of the material—with up to a 30 percent change.

The ability to control and measure mechanical properties could lead to promising materials for advanced acoustic (for example, microphones) and microwave devices. Also, scientists could use this new technique to reveal new physics rules for transitions in a material's atomic structure. Scientists could apply these rules to identify new materials for actuators, switches, magnetic field sensors, and computer memory.

When a material undergoes a phase change, its atomic structure is re-oriented, and many fundamental material properties can be altered including mechanical stiffness. This means the material can become harder or softer, which is an important consideration for applications which utilize material vibrations such as sensors or other electronic materials. Traditionally, scientists have studied phase changes and mechanical properties with neutron scattering and mechanical testing; unfortunately, these techniques cannot measure these materials' responses on the nanoscale. Ultimately, the nanoscale microstructure and resultant functionality needs to be understood to explain and improve device performance.

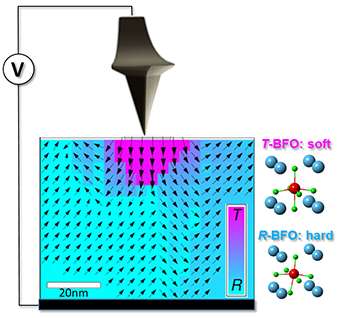

Researchers led by Oak Ridge National Laboratory have used an atomic force microscopy (AFM) technique to reveal voltage-induced changes in material stiffness in one of the most widely studied multifunctional material—bismuth iron oxide (BiFeO3). The use of a multi-frequency AFM technique allows the application of a voltage on nanometer length scales and found a phase transition as the origin for the change in material stiffness. Under an applied voltage, giant stiffness tunability was found. That is, the material stiffness changed reversibly over 30 percent, a quite dramatic change for these materials. Coupling with modeling allowed for a more detailed understanding of the observed phenomenon when the material becomes softer under an applied voltage. This discovery and detailed understanding of processes on nanometer length scale could have applications in advanced devices from high-performance microphones to new types of electronic memory as well as new imaging techniques to probe physics related to material transitions.

More information: Q Li et al. Giant elastic tunability in strained BiFeO3 near an electrically induced phase transition, Nature Communications (2015). DOI: 10.1038/ncomms9985

Journal information: Nature Communications

Provided by US Department of Energy