Controlling friction levels through on/off application of laser light

A National Institute for Materials Science (NIMS) research group discovered that the amount of friction force between organic molecules and a sapphire substrate in a vacuum can be changed repeatedly by starting and stopping laser light irradiation.

A NIMS research group led by Masahiro Goto, Distinguished Chief Researcher, Center for Green Research on Energy and Environmental Materials, and Michiko Sasaki, postdoctoral researcher, Center for Materials Research by Information Integration (currently a postdoctoral fellow at the University of Tokyo) discovered that the amount of friction force between organic molecules and a sapphire substrate in a vacuum can be changed repeatedly by starting and stopping laser light irradiation. This discovery could potentially lead to the development of technology enabling the movement of micromachines and other small driving parts to be controlled.

The performance of micromachines—used as moving components in small devices such as acceleration sensors and gyroscopes—is greatly affected by adhesion force (the attractive force between two or more materials that stick to each other). Adhesion force in a micromachine increases the friction force. Since increased friction force seriously impedes the movement of moving components, it is necessary to maintain a low level of adhesion force. In addition, if the level of friction force can be controlled, it may be feasible to control the movement of micromachines, leading to expansion of their use and enhancement of their functions. A great deal of attention was previously drawn to techniques enabling silicon-based materials, a major micromachine material, to be coated with diamond-like carbon, self-assembled monolayers, or fluorine-containing organic films in order to reduce friction force and thereby improve the movement of micromachines. However, it was difficult to control friction coefficients of two adjacent parts by coating them because the coefficients are determined predominantly by the materials used in these parts.

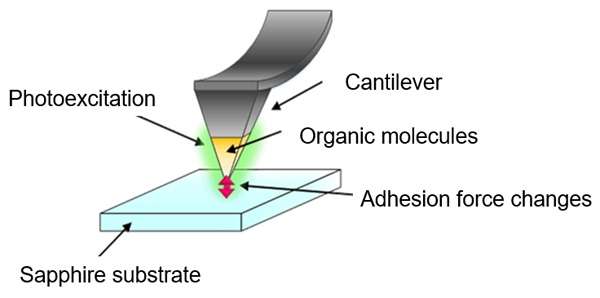

The research group invented a completely novel method of controlling friction force between materials using light irradiation. Specifically, the group irradiated a localized area of a cantilever coated with organic molecules with laser light and observed that the friction force between the coated cantilever and a sapphire substrate increased by 15% using a scanning probe microscopic technique known as friction force mode. Moreover, the group was able to increase and decrease the friction force repeatedly by switching the laser light on and off.

These findings may lead to the development of techniques to control the movement of micromachines and contribute to the identification of basic friction mechanism. While control of friction force by light at the nano level was achieved in this study, the technique also may be applicable to control of friction phenomena at the macro level.

More information: Michiko Sasaki et al. Control of friction force by light observed by friction force microscopy in a vacuum, Applied Physics Express (2017). DOI: 10.7567/APEX.10.015201

Provided by National Institute for Materials Science