Scientists create a low-cost, high-precision glass nanoengraving technique

In a joint study, a collaborative of Russian scientists has developed a mechanism of laser deposition of patterns on glass with a resolution of 1000 times lower than the width of a human hair. The lasers were focused through small glass spheres, rather than traditional lenses. This mechanism allows application of complex patterns to a glass surface relatively easily and inexpensively, obtaining a spatial resolution of less than 100 nanometers.

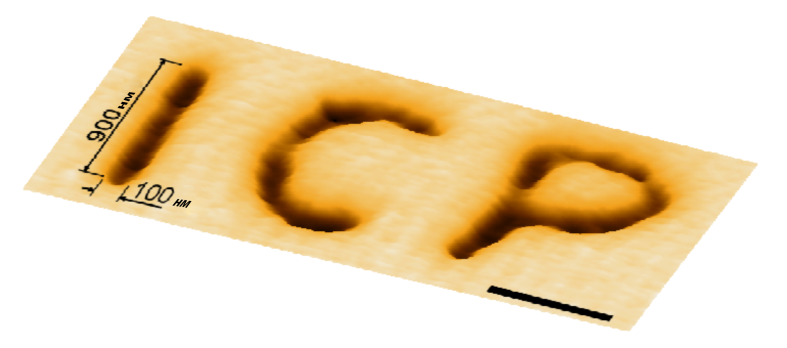

The proposed method will allow sufficiently quick and cheap creation of sensors and microchips at nanoscale. According to the scientists, it is much cheaper and technologically easier than any of previously used methods, and the new application allows deposition of the computer drawings on the glass surface with an acceptable resolution. To demonstrate this method, the abbreviation of the Institute of Chemical Physics (ICP) was deposited on glass with a resolution of about 100 nanometers. Nanoengraving is used to create ultra-precise circuits in microfluidics. The operating fluid can flow through the engraved channels, connecting various parts of the circuit. The smaller the size of such a circuit, the higher the engraving resolution.

A femtosecond laser allows deposition of complex, two- and three-dimensional patterns on the surface of transparent materials. Resolution—the minimum size of the pattern's image detail—is always a problem in these kinds of tasks, since it is limited (for physical reasons) by the laser wavelength. The higher the resolution, the smaller the size of patterns applied.

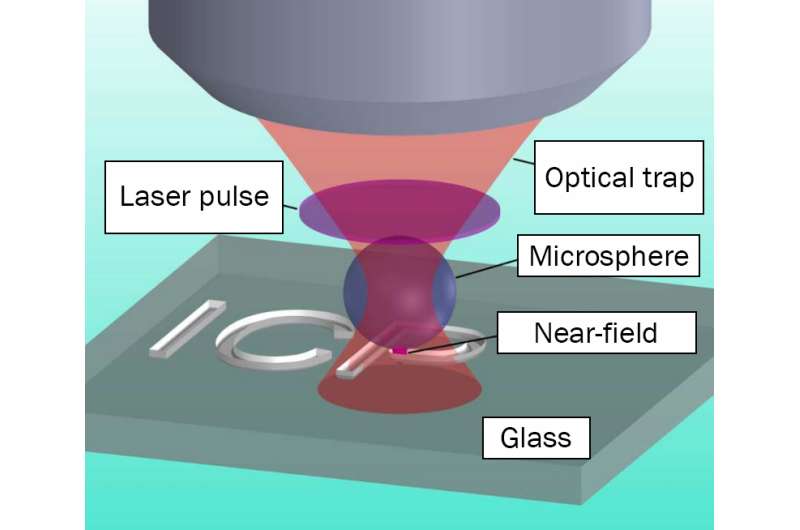

To improve the resolution, the near-field effect is often used. This method involves focusing a laser beam, using metal nanoparticles or a layer of dielectric microspheres as a "lens." However, these methods complicate the pattern's deposition process, as they are fixed in space.

In their work, the authors propose a different approach. Using a beam of light in fluid, they create a kind of a trap where they place glass microspheres. The advantage of this focusing method is that the trap can be moved, thereby moving the lens in space and focusing the laser to the desired area of the glass.

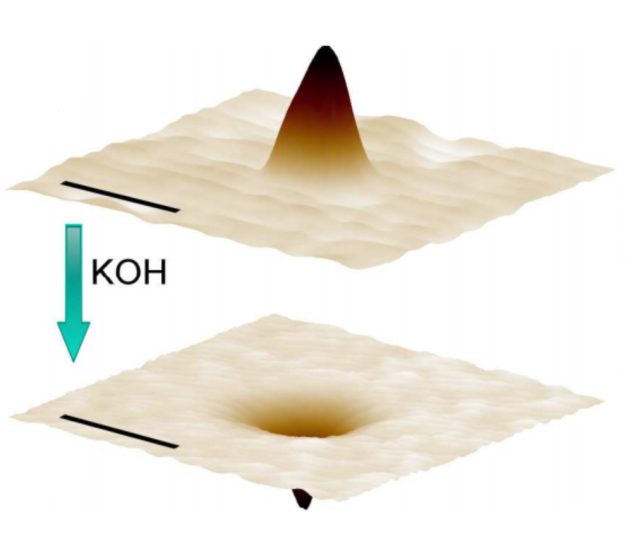

However, simply moving a laser beam along the surface is not enough. Exposure to the laser leads to the formation of hillocks but not craters. These hillocks are quite rough and wide, but the effect of alkali at a temperature of 90° C turns the hillocks into smooth craters with a smaller width. Such a two-step structuring allows achievement of a resolution below 100 nanometers (nm). By contrast, one-step structuring, in which the surface is treated only with a laser, does provide precision below 150 to 200 nm (depending on the complexity of the structure).

Initially, the glass surface is irradiated with a femtosecond laser. The laser pulse is focused by means of a glass bead, which is guided by an optical "trap" to a predetermined area of the glass. As a result, wide hillocks are formed on the surface of glass; after surface treatment with an alkaline solution, these hillocks are converted to smaller craters of more streamlined shapes.

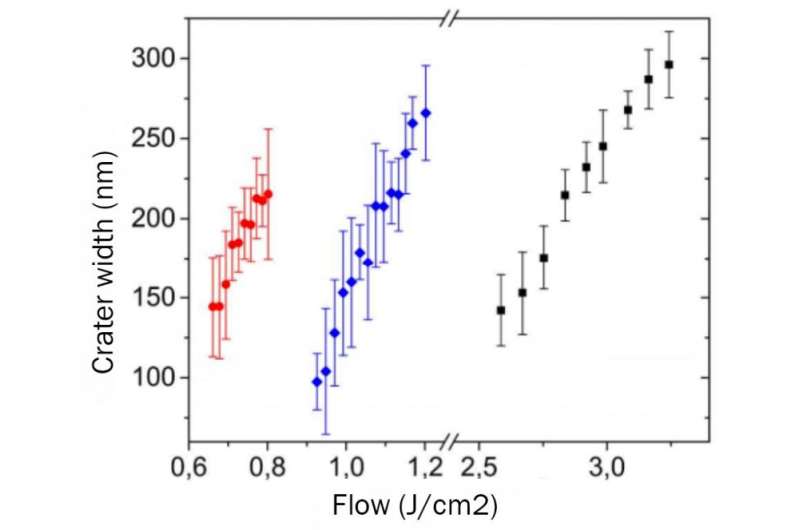

In addition to direct patterning, the scientists investigated dependence of the resolution, i.e. the crater size, from the laser power. The results showed that greater precision could be obtained with small spheres, which allow a resolution below 100 nm.

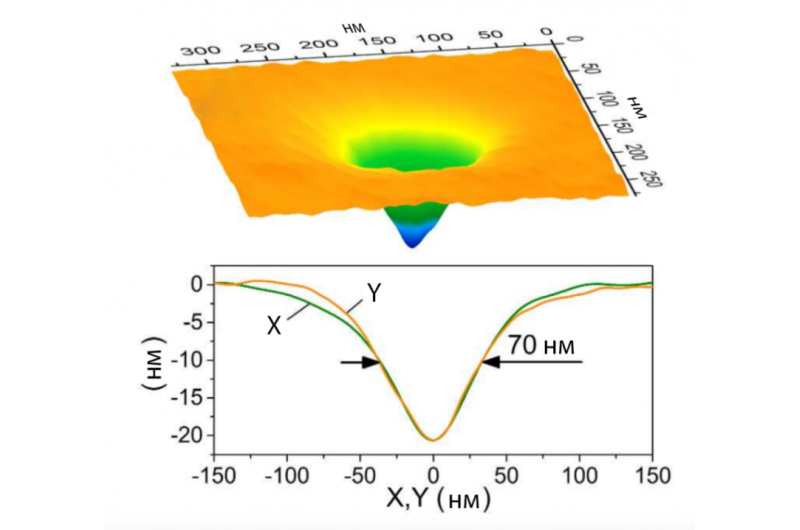

The minimum width of the crater obtained was 70 nm. The figure below shows this particular crater, and the chart shows the shape of the crater on two axes.

The publication demonstrate that the engraving technique enables relatively complex structures. To prove this, the glass surface was engraved with the abbreviation for the Institute of Chemical Physics (ICP). The average width of each letter is 100 nm, depth - 20 nm (see Fig. below with a scale - 500 nm).

"Creating thin grooves and channels can be used in chemistry and biology fields for the production of microfluidics and at various nano-plants," says Aleksander Shakhov, the article's co-author, post-graduate of the Faculty of General and Applied Physics at MIPT.

Channels for liquids engraved by these methods are used for the development of small, precise sensors working with liquids. The article in question also suggests a sufficiently fast and cheap mechanism for nanostructuring. Such an approach can allow rapid and technologically uncomplicated creation of inexpensive devices and sensors by applying complex structures of thin grooves and channels through which operating fluid will flow.

Journal information: ACS Applied Materials and Interfaces

Provided by Moscow Institute of Physics and Technology