Researchers discover importance of using right rubber for the job

Researchers from the University of Leicester have discovered that when it comes to rubbers, textured surfaces, and reproduction, more fluid formulations have greater reliability than those that are thick and sticky.

Rubber compounds are widely used to mould and produce copies of textured surfaces for scientific analysis, but so far little research has been done to establish which rubbers make the most reliable copies.

A new study published in the academic journal Scientific Reports, led by Professor Mark Purnell from the University of Leicester's Department of Geology, has discovered the best kind of rubber for reproduction.

Professor Purnell explained: "Roughness is something that everyone understands, and the difference between a rough and a smooth surface is obvious, but how do you compare two rough surfaces? How can you tell if surfaces - of the cylinders in your car engine, for example - are smooth enough to perform as they should?

"If you need to make precise measurements of a surface, and you can't take the original surface to the measuring instrument, you would need to analyse a replica. What we haven't known until now is whether the quality of the replica varies depending on the rubber used."

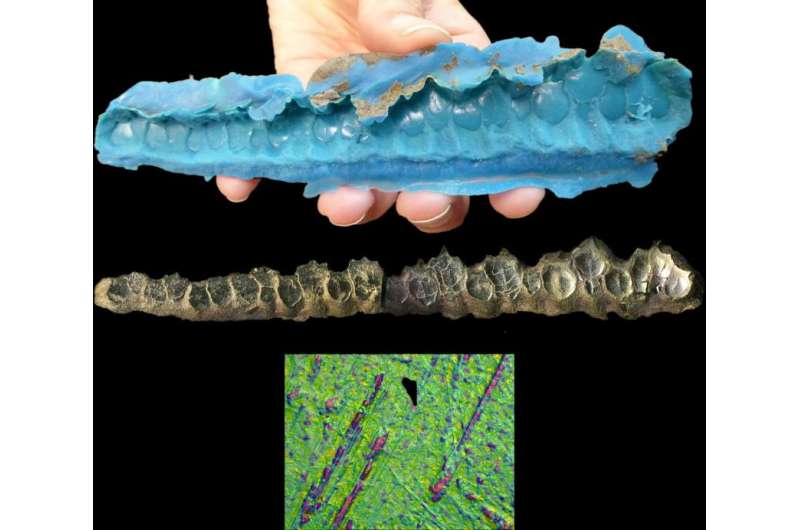

In order to find out what kind of rubber would make the best replica, the Leicester team made multiple copies of a rough and a smooth surface using different rubber compounds, which involved mixing the rubber and then pouring it onto a surface until it solidified.

They analysed the measurements for exactly the same areas of the surfaces, comparing them with each other and with the original surface.

They found that rubber replicas are not comparable with one another and that, in general, high viscosity rubber compounds which pour as thick liquids make replicas that are less similar - and less desirable - compared to the original surface.

Robert Goodall, University of Leicester PhD student and lead author of the paper, added: "If you want good results - with all the ridges and bumps on a surface reproduced at the same scale as the original - you need to use the right rubber for the job."

The types of surface that scientists and engineers make copies of include skin, teeth, superconductor components in particle accelerators, and various tools, including forensic and archaeological investigations. Surfaces are carefully measured to quantify their roughness and texture, but this can be surprisingly tricky.

The importance of a surface's roughness can be seen in car engines, where if the walls of the engine's cylinders are too smooth they will seize, meaning that the surface needs to be just rough enough to carry a film of lubricant to maintain a smooth piston action.

Techniques have now been developed that can make measurements of ridges, bumps and dimples, down to the nanometre scale - less than 1/100 the thickness of a human hair.

More information: Accuracy and Precision of Silicon Based Impression Media for Quantitative Areal Texture Analysis, Scientific Reports 5, Article number: 10800. DOI: 10.1038/srep10800

Journal information: Scientific Reports

Provided by University of Leicester