Silver-glass sandwich structure acts as inexpensive color filter

The engineering world just became even more colorful.

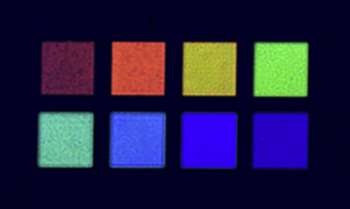

Northwestern University researchers have created a new technique that can transform silver into any color of the rainbow. Their simple method is a fast, low-cost alternative to color filters currently used in electronic displays and monitors.

"Our technique doesn't require expensive nanofabrication techniques or a lot of materials," said Koray Aydin, assistant professor of electrical engineering and computer science at Northwestern's McCormick School of Engineering. "And it can be completed in a half hour or so."

The filter's secret lies within its "sandwich-like" structure. Aydin and his team created a three-layer design, where glass is wedged two thin layers of silver film. The silver layers are thin enough to allow optical light to pass through, which then transmits a certain color through the glass and reflects the rest of the visible spectrum. By changing the thickness of the glass, Aydin was able to filter and produce different colors.

"Controlling the thickness of the glass controls the color," Aydin said. "This way, we can create any color desired."

Supported by the Air Force Office of Scientific Research, the research was published online in ACS Photonics on January 28, 2015. PhD student Zhongyang Li and postdoctoral researcher Serkan Butun, who are both in Aydin's lab, were coauthors of the paper.

By making the bottom silver layer even thicker, Aydin found that the structure also acts as a color absorber because it traps light between the two metal layers. The team demonstrated a narrow bandwidth super absorber with 97 percent maximum absorption, which could have potential applications for optoelectric devices with controlled bandwidth, such as narrow-band photodetectors and light-emitting devices. The performance of Aydin's structure is comparable to that of nanostructure-based devices but bypasses the complications of nanotechnology.

"People in the nanophotonics community are dealing with nanostructures, making nanoparticles, and using lithography or chemistry techniques," he said. "That can be really challenging. We're combatting that difficulty with a simple design."

Aydin is also developing a similar structure out of aluminum and glass to filter or absorb ultraviolet spectrum. By controlling the thickness of the materials, he plans to design devices for other wavelengths of light.

More information: ACS Photonics, pubs.acs.org/doi/abs/10.1021/ph500410u

Provided by Northwestern University