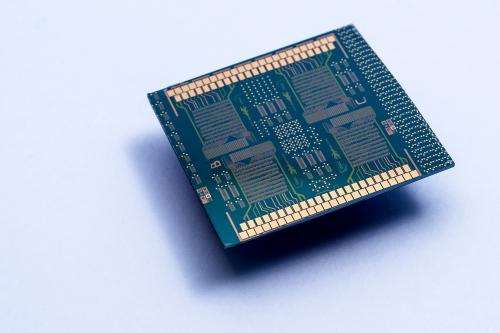

Thin-film hybrid oxide-organic microprocessor

Holst Centre, imec and their partner Evonik have realized a general-purpose 8-bit microprocessor, manufactured using complementary thin-film transistors (TFTs) processed at temperatures compatible with plastic foil substrates (250°C). The new "hybrid" technology integrates two types of semiconductors—metal-oxide for n-type TFTs (iXsenic, Evonik) and organic molecules for p-type TFTs—in a CMOS microprocessor circuit, operating at unprecedented for TFT technologies speed—clock frequency 2.1kHz. The breakthrough results were published online in Scientific Reports, an open access journal from the publisher of Nature.

Low temperature thin-film electronics are based on organic and metal-oxide semiconductors. They have the potential to be produced in a cost effective way using large-area manufacturing processes on plastic foils. Thin-film electronics are, therefore, attractive alternatives for silicon chips in simple IC applications, such as radio frequency identification (RFID) and near field communication (NFC) tags and sensors for smart food packaging, and in large-area electronic applications, such as flexible displays, sensor arrays and OLED lamps. Holst Centre's (imec and TNO) research into thin-film electronics aims at developing a robust, foil-compatible, high performance technology platform, which is key to making these new applications become a reality.

The novel 8-bit microprocessor performs at a clock frequency of 2.1 kHz. It consists of two separate chips: a processor core chip and a general-purpose instruction generator (P2ROM). For the processor core chip, a complementary hybrid organic-oxide technology was used (p:n ratio 3:1). The n-type transistors are 250°C solution-processed metal-oxide TFTs with typically high charge carrier mobility (2 cm2/Vs). The p-type transistors are small molecule organic TFTs with mobility of up to 1 cm2/Vs.

The complementary logic allows for a more complex and complete standard cell library, including additional buffering in the core and the implementation of a mirror adder in the critical path. These optimizations have resulted in a high maximum clock frequency of 2.1kHz. The general-purpose instruction generator or P2ROM is a one-time programmable ROM memory configured by means of inkjet printing, using a conductive silver ink. The chip is divided into a hybrid complementary part and a unipolar n-TFT part and is capable of operating at frequencies up to 650 Hz, at an operational voltage of Vdd=10V.

Journal information: Nature , Scientific Reports

Provided by IMEC