Synthesis of a new lean rare earth permanent magnetic compound superior to Nd2Fe14B

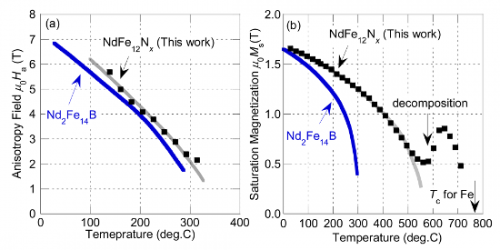

A research group led by Dr. Kazuhiro Hono at the National Institute for Materials Science (NIMS) in Tsukuba, Japan, synthesized a new magnetic compound, which requires a lesser amount of rare earth element than the currently used neodymium iron boron compound. The ratio of neodymium, iron and nitrogen in the new compound, NdFe12N, is 1:12:1. Its neodymium concentration is 17% compared to 27% for the neodymium iron boron compound known as Nd2Fe14B, the main component used in the strongest permanent magnets. Furthermore, the intrinsic hard magnetic properties were found to be superior to those of Nd2Fe14B. The result of this research will be published in Scripta Materialia on October 20, 2014.

Neodymium permanent magnets are the strongest magnets used in many industrial applications such as hard disk drives, cell phones, hybrid electric vehicles and wind turbines. Recently, their usage is increasing rapidly due to the growth of the production of hybrid and electric vehicles. Rare earth elements such as neodymium and dysprosium are essential components of these magnets. Since one country dominates the production of rare earth metals, there is some concern regarding the stable supply of rare earth elements for the increasing demand of these magnets. This led to worldwide intensive research to reduce the content of rare earth elements in high-performance permanent magnets.

The neodymium permanent magnet, invented by Dr. Masato Sagawa in 1982, is composed of the Nd2Fe14B compound and some minor nonmagnetic components. No magnetic compound has been able to challenge this compound during the last 32 years. A different type of magnetic compound, NdFe11TiN, has been known to exist in the long history of rare earth permanent magnet research. However, the alloying of the non-magnetic Ti was necessary to stabilize this compound, causing its magnetic properties to be inferior to those of Nd2Fe14B; therefore, not much attention has been paid to it. Since the compound becomes unstable without Ti, no one has succeeded in synthesizing it only with magnetic elements. In this study, the NdFe12N compound was synthesized successfully without non-magnetic Ti. The NdFe12 thin film was grown on a tungsten layer using a sputtering method, and then the NdFe12N was obtained by nitriding the NdFe12 layer. The small lattice misfit with the tungsten layer made the growth of the unstable NdFe12N compound possible. Although the compound was processed in the form of a thin film, they found it can be grown to the thickness of 350 nm.

The ratio of neodymium, iron and nitrogen in the NdFe12N is 1:12:1. It requires a much smaller proportion of Nd, only 17% of the entire mass, which is substantially smaller than 27% required for Nd2Fe14B. Furthermore, its intrinsic hard magnetic properties were found to be superior to those of Nd2Fe14B. In particular, the Curie temperature of the new compound is higher than that of Nd2Fe14B by 200ºC. This feature is particularly attractive for the application to traction motors of hybrid and pure electric vehicles, where the operation temperature exceeds 150ºC.

The future direction is the establishment of a processing route to synthesize a large quantity of powders of this compound and to manufacture bulk magnets. This research has just started; however, the discovery of a new magnetic compound superior to Nd2Fe14B for the first time in 32 years reinvigorates the area.

This research was performed at the Elements Strategy Initiative Center for Magnetic Materials (ESICMM), which was established at NIMS in the scheme of Elements Strategy Initiative Project by MEXT, Japan. The work was in part supported by the Japan Science and Technology Agency, CREST.

More information: Y. Hirayama, Y.K. Takahashi, S. Hirosawa, K. Hono, NdFe12Nx hard-magnetic compound with high magnetization and anisotropy field, Scripta Materialia, Available online 20 October 2014, ISSN 1359-6462, dx.doi.org/10.1016/j.scriptamat.2014.10.016.

Journal information: Scripta Materialia

Provided by National Institute for Materials Science