February 6, 2013 report

Researchers print transistor on nearly transparent nanopaper

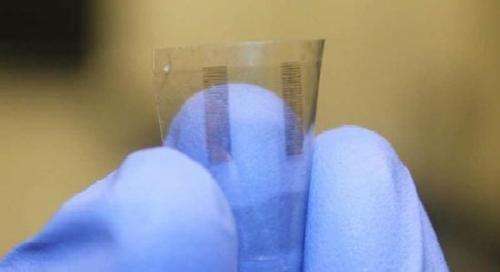

(Phys.org)—Researchers at the University of Maryland have succeeded in creating a transistor using a new kind of paper as a base. As the team describes in their paper published in the journal ACS Nano, they were able to overcome the limitations of ordinary paper by creating very flat nanopaper that allowed for printing a layered transistor.

As part of an effort by many researchers the world over to use renewable resources, scientists have turned to paper as a base for creating electronic devices. To that end, research efforts have yielded such products as paper batteries, light emitting diodes and several types of circuits. Thus far however, efforts to make paper based transistors have been disappointing due to the roughness of ordinary paper—the bumps and valleys can be on the micrometer scale, whereas transistor layers can only tolerate differences of a few hundred nanometers.

To overcome this problem the researchers created nanopaper by treating paper pulp with oxidizing enzymes and mechanically beating it till very flat. The end result is paper that is 84 percent transparent and exceptionally flat—its fibers have an average diameter of just 10nm.

Because the nanopaper is as flat as plastic, the researchers were able to print electronics on it, starting with a base layer of carbon nanotubes. Next a dielectric ink was applied via printing, followed by a coat of semiconducting ink. The transistor was completed by applying another nanotube layer that served as both electrodes and as a means of structural support. In testing the finished product, the researchers found the transistor functioned as planned, and even sustained a loss of just 10 percent efficiency when slightly bent.

The research team acknowledges that their nanopaper based transistor is not yet efficient enough to compete with materials currently in use in electronic devices, but suggests that some tweaking might lessen the wrinkling that occurs with the paper as the ink dries, increasing efficiency. If so, consumers might someday soon find themselves using computers, smartphones, etc., with transistors in them built using a renewable resource—and that might lead to devices that can be easily recycled as well.

More information: Highly Transparent and Flexible Nanopaper Transistor, ACS Nano, Just Accepted Manuscript. DOI: 10.1021/nn304407r

Abstract

Green electronics based on paper substrates is emerging as a field with more and more intensive research and commercial interests due to its unique properties, such as flexibility, cost efficiency, lightweight and renewability. Due to its excellent optical transmittance and surface roughness, nanopaper can render many types of electronics that are not possible on regular paper. However, there are tremendous challenges of integrating devices in nanopaper due to its shape stability during processing and rough surface. We have demonstrated for the first time that flexible transparent organic field-effect transistors (OFETs) with carbon nanotube networks as source/drain contact can be fabricated on tailored nanopaper substrates. Both good electrical characteristics and excellent mechanical flexibility were observed, which may be due to the large binding energy between polymer dielectric and cellulose nanopaper and the effective stress release from the fibrous substrate. Only a 10% decrease in mobility was observed when the nanopaper transistors were being bent. The nanopaper transistor also showed excellent optical transmittance up to 83.5%. The device configuration can be applied to many other semiconductor materials toward flexible green electronics.

Journal information: ACS Nano

© 2013 Phys.org