January 25, 2013 report

iRobot proposes 3-D printing with less human intervention

(Phys.org)—iRobot Corporation, the Bedford, Massachusetts-based makers of Roomba, have a wish list for 3-D printing that goes something like this: Cut out the human labor, automate everything, and the result is reduced manufacturing costs and higher product quality. Putting their efforts into action, iRobot filed a patent last year for just that reason. Their patent calls for a 3-D printer that produces completely finished products without the need for humans to assemble or finish the object.

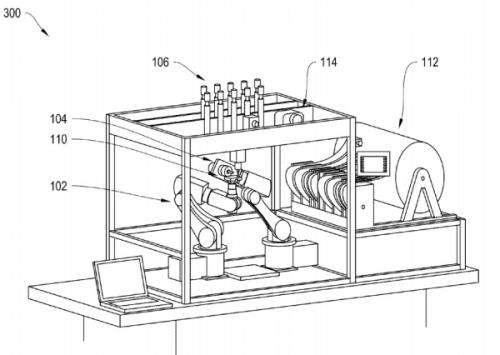

The Robotic Fabricator, as their patent is called, presents methods in which an all in one automated fabricator would make things and put them together too. The patent filing makes note of tools toward this end. The system would include a tool-head for manufacturing, and manipulators.

"In traditional 3D printing," said the iRobot filers, "designs must still be divided into parts for production, and a trained individual assembles the fabricated parts into the final product after printing."

The human involvement in traditional 3-D printing creates increased factory safety risks. As important, they argue that the automated system that they are recommending reduces the risk of failure of the end product.

"Connectors, fasteners, seams, and similar interfaces are frequently a source of failure in the end product. A fabrication device that reduces the number of connectors, fasteners, seams, and similar component interfaces increases the quality of the end product and reduces product failure."

Included in their patent discussion is how fabrication could be centered around a six-axis industrial robotic manipulator (primary manipulator) that handles the product from seed component to mature product. "The primary manipulator positions the product for manufacturing operations such as additive and subtractive manufacturing (3D printing, milling and drilling). A secondary manipulator handles component pick-and-place and secondary manufacturing operations such as wire placement and hardware testing."

As an option, they suggest that the system could include high-precision sensors to measure parameters and characteristics of the device while the process is taking place. The feedback from the sensors would allow the system to estimate product qualities, such as tolerances, dimensions, and mass.

The processes described in the patent, including Robocasting, would allow for products composed of materials including but not limited to ABS, polycarbonate, silicone rubbers, urethane rubbers, and plastics, low melting temperature metals, and combinations of these materials.

Reactions to news of the patent filing for a full printing and finishing device have been favorable, as a means of taking the 3-D printing process up higher, to a level that can handle the connectors, seams, and fasteners that lock the parts together.

More information: Patent application

via 3ders

© 2013 Phys.org