Miniaturized ultra-small platinum cylinders weaken when their constituents reduced in number

Miniaturizing microscopic metallic objects while enhancing their strength is critical to developing high-performance devices that integrate transistor-like electronics with mechanical components. When these objects consist of small crystals, or grains, such as polycrystalline nanopillars, their mechanical behavior is difficult to predict because the grains vary in size and orientation. Researchers from the California Institute of Technology, USA, and A*STAR Institute of High Performance Computing (IHPC), Singapore, have now determined how miniaturization and intrinsic granular structure impact the deformation of ultra-small platinum cylinders.

The team used a combined experimental and computational approach to overcome the knowledge gap hindering the production of reliable micro- and nano-electromechanical devices. Team member Zhaoxuan Wu from IHPC explains that this approach allowed them to reduce the size of the experimental samples to tens of nanometers. It also allowed them to perform large-scale atomic simulations on comparable nanostructures, which provided a means to directly link structure and mechanical properties. "This is rarely achievable in such studies," he notes.

The researchers first generated a template by depositing a polymer film on a gold-coated silicon surface and perforating it with nano- to micrometer-sized cylindrical holes. Next, they synthesized the metal nanostructures in these holes from a platinum precursor solution. Dissolving the template then produced nanopillars that displayed well-defined grains of similar sizes and grain boundaries, or interfaces.

Compression experiments on the nanostructures showed that the thinnest nanopillars remained almost cylindrical under low pressure but weakened dramatically, and bent irreversibly, under high pressure. In contrast, wider nanopillars exhibited a smoother deformation and delayed failure. This 'smaller is weaker' trend is contrary to the fate observed for metallic single crystals: they become stronger with smaller diameters. Wu and co-workers also found that reducing the number of grains across a nanopillar's diameter weakened the structure.

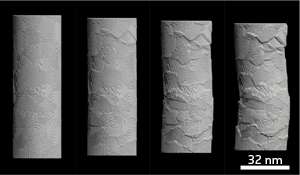

In agreement with their experimental results, the researchers' numerical simulations revealed that the compressed nanopillars gradually underwent reversible and subsequent irreversible deformation (see image). Moreover, the simulations indicated the origin within the nanostructures of the irreversible deformation and dislocation motions. The nanopillars contain a high density of grain boundaries that promote the formation of dislocations. These dislocations, through which a specific type of deformation develops, propagate across an entire grain or from one grain to another inside the cores. Close to the nanopillar surface, the grains easily slide against each other to create atom-sized steps, reducing material strength.

"We are further examining the effects of microstructural flaws and oxidations on the mechanical behavior of nanomaterials," says Wu.

More information: Gu, X. W., Loynachan, C. N., Wu, Z., Zhang, Y.-W., Srolovitz, D. J. & Greer, J. R. Size-dependent deformation of nanocrystalline Pt nanopillars. Nano Letters 12, 6385–6392 (2012). dx.doi.org/10.1021/nl3036993

Journal information: Nano Letters