Producing high-tech steel cheaply and efficiently

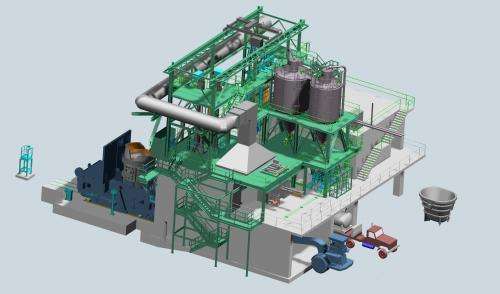

A new plant for desulfurizing pig iron is reducing the costs of steel production. Developed by Siemens, this innovative process makes it possible to more precisely dose the various desulfurizing agents that are injected into the molten metal and do so more economically. The technology is based on the patented Simetal Feldhaus process, which has been adopted and further developed by Siemens. A plant of this type is currently under construction in Brazil at steel producer ArcelorMittal Monlevade S.A.

Pig iron is produced by heating iron ore together with coke and various additives in a blast furnace. Sulfur present in these materials typically results in a sulfur content in the pig iron of between 200 and 600 parts per million (ppm). Depending on the grade of steel required, this sulfur content must be reduced - to as little as 10 ppm for modern high-performance steels. For this purpose, desulfurizing agents such as burnt lime, calcium carbide, and magnesium are injected into the molten metal. Of the three agents, magnesium is the most effective but also the most expensive. A higher concentration of magnesium is used whenever a large reduction in sulfur content is required and processing time is limited. Allowing for variations in the precise process parameters, the production of one metric ton of steel typically requires the addition of around 0.7 kilograms of magnesium and just under three kilograms of burnt lime. A plant with an annual output of one million metric tons of steel will therefore face production costs of over €1.5 million for magnesium alone.

The desulfurizing agents are added individually or in combination by means of a carrier gas injected into the molten metal via a so-called lance. Here the major challenge consists in maintaining a precise, predefined flow of the individual agents despite their different physical characteristics: burnt lime and calcium carbide are fine powders; magnesium is a granulate. To ensure precise dosing of the magnesium granules, Siemens has adopted the Feldhaus process, which has been in use at a Düsseldorf steel plant since 1999. Unlike the conventional pressure vessel-based techniques used to inject powder agents, this pneumatic conveying process ensures precise dosing of the magnesium. In addition, the desulfurizing plant has been enhanced in such a way that the dosage of the powder agents can be controlled more precisely. This has involved the redesign of the containers in order to ensure that the powders flow evenly into the stream of gas.

The new plant in Brazil will make it possible to use desulfurizing agents more cost-effectively, control the sulfur concentrations in the end product with greater precision, and reduce the magnesium requirement of a steelworks by around 10 percent.

Provided by Siemens