Scientists Strive to Replace Silicon with Graphene on Nanocircuitry

(PhysOrg.com) -- Scientists have made a breakthrough toward creating nanocircuitry on graphene, widely regarded as the most promising candidate to replace silicon as the building block of transistors. They have devised a simple and quick one-step process for creating nanowires, tuning the electronic properties of reduced graphene oxide and thereby allowing it to switch from being an insulating material to a conducting material.

The technique works with multiple forms of graphene and is poised to become an important finding for the development of graphene electronics. The research appears in the June 11, 2010, issue of the journal Science.

Scientists who work with nanocircuits are enthusiastic about graphene because electrons meet with less resistance when they travel along graphene compared to silicon and because today's silicon transistors are nearly as small as allowed by the laws of physics. Graphene also has the edge due to its thickness - it's a carbon sheet that is a single atom thick. While graphene nanoelectronics could be faster and consume less power than silicon, no one knew how to produce graphene nanostructures on such a reproducible or scalable method. That is until now.

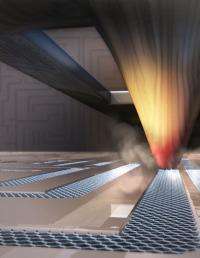

"We've shown that by locally heating insulating graphene oxide, both the flakes and epitaxial varieties, with an atomic force microscope tip, we can write nanowires with dimensions down to 12 nanometers. And we can tune their electronic properties to be up to four orders of magnitude more conductive. We've seen no sign of tip wear or sample tearing," said Elisa Riedo, associate professor in the School of Physics at the Georgia Institute of Technology.

On the macroscale, the conductivity of graphene oxide can be changed from an insulating material to a more conductive graphene-like material using large furnaces. Now, the research team used TCNL to increase the temperature of reduced graphene oxide at the nanoscale, so they can draw graphene-like nanocircuits. They found that when it reached 130 degrees Celsius, the reduced graphene oxide began to become more conductive.

"So the beauty of this is that we've devised a simple, robust and reproducible technique that enables us to change an insulating sample into a conducting nanowire. These properties are the hallmark of a productive technology," said Paul Sheehan, head of the Surface Nanoscience and Sensor Technology Section at the Naval Research Laboratory in Washington, D.C.

The research team tested two types of graphene oxide - one made from silicon carbide, the other with graphite powder.

"I think there are three things about this study that make it stand out," said William P. King, associate professor in the Mechanical Science and Engineering department at the University of Illinois at Urbana-Champaign. "First, is that the entire process happens in one step. You go from insulating graphene oxide to a functional electronic material by simply applying a nano-heater. Second, we think that any type of graphene will behave this way. Third, the writing is an extremely fast technique. These nanostructures can be synthesized at such a high rate that the approach could be very useful for engineers who want to make nanocircuits."

"This project is an excellent example of the new technologies that epitaxial graphene electronics enables," said Walt de Heer, Regent's Professor in Georgia Tech's School of Physics and the original proponent of epitaxial graphene in electronics. His study led to the establishment of the Materials Research Science and Engineering Center two years ago. "The simple conversion from graphene oxide to graphene is an important and fast method to produce conducting wires. This method can be used not only for flexible electronics, but it is possible, sometime in the future, that the bio-compatible graphene wires can be used to measure electrical signals from single biological cells."

Provided by Georgia Institute of Technology