European researchers make breakthrough in developing super-material graphene

(PhysOrg.com) -- A collaborative research project has brought the world a step closer to producing a new material on which future nanotechnology could be based. Researchers across Europe, including the UK's National Physical Laboratory (NPL), have demonstrated how an incredible material, graphene, could hold the key to the future of high-speed electronics, such as micro-chips and touchscreen technology.

Graphene has long shown potential, but has previously only been produced on a very small scale, limiting how well it could be measured, understood and developed. A paper published on the 17th January, in Nature Nanotechnology explains how researchers have, for the first time, produced graphene to a size and quality where it can be practically developed, and successfully measured its electrical characteristics. These significant breakthroughs overcome two of the biggest barriers to scaling up the technology.

A technology for the future

Graphene is a relatively new form of carbon made up of a single layer of atoms arranged in a honeycomb shaped lattice. Despite being one atom thick and chemically simple, graphene's is extremely strong and highly conductive, making it ideal for high-speed electronics, photonics and beyond.

Graphene is a strong candidate to replace semiconductor chips. Moore's Law observes that the density of transistors on an integrated circuit doubles every two years, but silicon and other existing transistor materials are thought to be close to the minimum size where they can remain effective. Graphene transistors can potentially run at faster speeds and cope with higher temperatures. Graphene could be the solution to ensuring computing technology to continue to grow in power whilst shrinking in size, extending the life of Moore's law by many years.

Large microchip manufacturers such as IBM and Intel have openly expressed interest in the potential of graphene as a material on which future computing could be based.

Graphene also has potential for exciting new innovations such as touchscreen technology, LCD displays and solar cells. Its unparalleled strength and transparency make it perfect for these applications, and its conductivity would offers a dramatic increase in efficiency on existing materials.

Growing to a usable size while maintaining quality

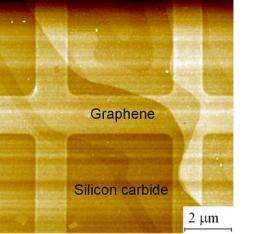

Until now graphene of sufficient quality has only been produced in the form of small flakes of tiny fractions of a millimeter, using painstaking methods such as peeling layers off graphite crystals with sticky tape. Producing useable electronics requires much larger areas of material to be grown. This project saw researchers, for the first time, produce and successfully operate a large number of electronic devices from a sizable area of graphene layers (approximately 50 mm2).

The graphene sample, was produced epitaxially - a process of growing one crystal layer on another - on silicon carbide. Having such a significant sample not only proves that it can be done in a practical, scalable way, but also allowed the scientists to better understand important properties.

Measuring resistance

The second key breakthrough of the project was measuring graphene's electrical characteristics with unprecedented precision, paving the way for convenient and accurate standards to be established. For products such as transistors in computers to work effectively and be commercially viable, manufacturers must be able to make such measurements with incredible accuracy against an agreed international standard.

The international standard for electrical resistance is provided by the Quantum Hall Effect, a phenomenon whereby electrical properties in 2D materials can be determined based only on fundamental constants of nature.

The effect has, until now, only been demonstrated with sufficient precision in a small number of conventional semiconductors. Furthermore, such measurements need temperatures close to absolute zero, combined with very strong magnetic fields, and only a few specialised laboratories in the world can achieve these conditions.

Graphene was long tipped to provide an even better standard, but samples were inadequate to prove this. By producing samples of sufficient size and quality, and accurately demonstrate Hall resistance, the team proved that graphene has the potential to supersede conventional semiconductors on a mass scale.

Furthermore graphene shows the Quantum Hall Effect at much higher temperatures. This means the graphene resistance standard could be used much more widely as more labs can achieve the conditions required for its use. In addition to its advantages of operating speed and durability, this would also speed the production and reduce costs of future electronics technology based on graphene

Prof Alexander Tzalenchuk from NPL's Quantum Detection Group and the lead author on the Nature Nanotechnology paper observes: "It is truly sensational that a large area of epitaxial graphene demonstrated not only structural continuity, but also the degree of perfection required for precise electrical measurements on par with conventional semiconductors with a much longer development history."

Where now?

The research team isn't content to leave it there. They are hoping to go on to demonstrate even more precise measurement, as well as accurate measurement at even higher temperatures. They are currently seeking EU funding to drive this forward.

Dr JT Janssen, an NPL Fellow who worked on the project, said: "We've laid the groundwork for the future of graphene production, and will strive in our ongoing research to provide greater understanding of this exciting material. The challenge for industry in the coming years will be to scale the material up in a practical way to meet new technology demands. We have taken a huge step forward, and once the manufacturing processes are in place, we hope graphene will offer the world a faster and cheaper alternative to conventional semiconductors".

The Quantum Hall Effect

This appears where an electric current flows through a two dimensional material in a perpendicular magnetic field and the voltage in the material is measured perpendicular to both the current flow and the field. Within certain periodic intervals of field, the ratio of this transverse voltage to the current, known as the Hall resistance, is determined only by a known combination of fundamental constants of nature - the Planck's constant h and the electron charge e.

Because of this universality, the Quantum Hall effect provides the basis for the resistance standard in principle independent of a particular sample, material or measurement setup.

The Quantum Hall effect has, until now, only been accurately demonstrated with sufficient precision in a small number of conventional semiconductors, such as Si and group III-V heterostructures. Because of its unique electronic structure, graphene was long tipped to provide an even better standard, but the small size of graphene flakes and insufficient quality of early graphene films did not allow accurate measurements to be performed.

More information: The Nature Nanotechnology paper can be viewed here dx.doi.org/10.1038/NNANO.2009.474

Provided by National Physical Laboratory