September 15, 2016 report

New nanocrystalline alloy that combines mechanical strength with high-temperature creep resistance

(Phys.org)—A combined team of researchers affiliated with the Army Research Laboratory at Aberdeen Proving Ground, Arizona State University and the University of North Texas has developed a nanocrystalline alloy that combines high mechanical strength with high-temperature creep resistance. In their paper published in the journal Nature, the team describes how they created the material and its properties. Jonathan Cormier with Institut Pprime, UPR CNRS offers a News & Views piece on the work done by the team in the same journal issue and outlines some of the hurdles that stand in the way of the alloy being used in industrial applications.

As Cormier notes, there are some applications (such as airplane engines) that require metal to be both extremely strong and resistant to creep (deformations that occur due to long term stress) at high temperatures. Currently, superalloys are used, but they have their limits, and for that reason, new alloys with better features are being created to provide benefits such as more efficiency (which could mean reducing fuel consumption). In this new effort, the researchers have found a way to improve creep with one nanocrystalline alloy they have developed—such alloys typically have poor creep resistance due to the extremely small grains used to make them.

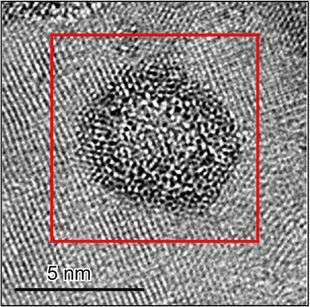

To make their alloy, the researchers started with very small grains of copper and then added tantalum particles to the boundaries between the individual grains to prevent them from migrating—the source of creep. The result (which involved multiple millings at −196°C) was an alloy with excellent creep properties due to a stable microstructure—testing showed it to be approximately six to eight magnitudes of order better than other nanocrystalline alloys.

The development of the alloy is significant because it shows that a nanocrystalline alloy could be made to be creep resistant; yet there are still problems preventing its use in industrial applications—as Cormier notes, foremost among them are concerns about whether the process could be ported to mass production. Also, the increased density boundaries in the alloy make it more susceptible to oxidation and the creep resistance of the alloy needs to work at higher temperatures than the new alloy can sustain.

More information: K. A. Darling et al. Extreme creep resistance in a microstructurally stable nanocrystalline alloy, Nature (2016). DOI: 10.1038/nature19313

Abstract

Nanocrystalline metals, with a mean grain size of less than 100 nanometres, have greater room-temperature strength than their coarse-grained equivalents, in part owing to a large reduction in grain size. However, this high strength generally comes with substantial losses in other mechanical properties, such as creep resistance, which limits their practical utility; for example, creep rates in nanocrystalline copper are about four orders of magnitude higher than those in typical coarse-grained copper. The degradation of creep resistance in nanocrystalline materials is in part due to an increase in the volume fraction of grain boundaries, which lack long-range crystalline order and lead to processes such as diffusional creep, sliding and rotation3. Here we show that nanocrystalline copper–tantalum alloys possess an unprecedented combination of properties: high strength combined with extremely high-temperature creep resistance, while maintaining mechanical and thermal stability. Precursory work on this family of immiscible alloys has previously highlighted their thermo-mechanical stability and strength, which has motivated their study under more extreme conditions, such as creep. We find a steady-state creep rate of less than 10−6 per second—six to eight orders of magnitude lower than most nanocrystalline metals—at various temperatures between 0.5 and 0.64 times the melting temperature of the matrix (1,356 kelvin) under an applied stress ranging from 0.85 per cent to 1.2 per cent of the shear modulus. The unusual combination of properties in our nanocrystalline alloy is achieved via a processing route that creates distinct nanoclusters of atoms that pin grain boundaries within the alloy. This pinning improves the kinetic stability of the grains by increasing the energy barrier for grain-boundary sliding and rotation and by inhibiting grain coarsening, under extremely long-term creep conditions. Our processing approach should enable the development of microstructurally stable structural alloys with high strength and creep resistance for various high-temperature applications, including in the aerospace, naval, civilian infrastructure and energy sectors.

Journal information: Nature

© 2016 Phys.org