September 4, 2015 report

Layering technique allows for creating graphene fiber that maintains conductivity and strength

(Phys.org)—A team of researchers working at Rensselaer Polytechnic Institute has found a way to create a graphene fiber that is stronger and maintains conductive properties better than prior efforts. In their paper published in the journal Science, the team describes their technique and suggests possible uses for the resultant material.

Graphene has excellent conductivity and mechanical strength, when in its 2D form—getting it to maintain both attributes when using it to make 3D products, however has been problematic. In this new effort, the researchers report on a new technique they developed for creating grahene fiber that offers higher thermal and electrical conductivity and better strength than other methods.

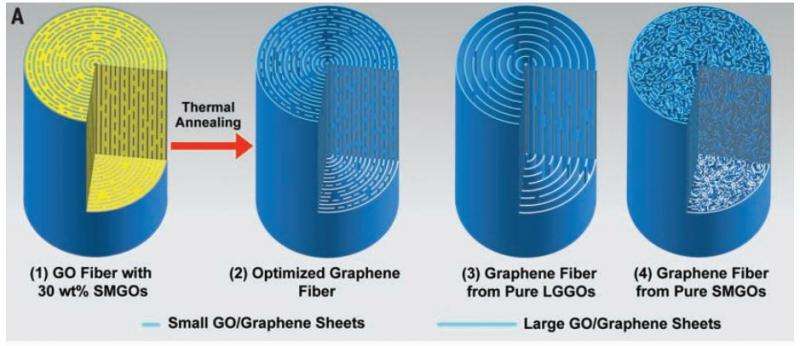

Prior research has shown that it is possible to make graphene fibers by creating graphene oxide (GO) sheets in a liquid solution using a wet-spinning method—the graphene fibers are created using a reduction of the GO fibers technique. Unfortunately, the material that is created does not have enough of the positive attributes of 2D graphene to make it useful. In this new effort, the researchers take the same approach, but go one step further—they weave sheets the same size as others have produced, then weave some more that are smaller, then they weave the two layers together—this allows for filling in the "voids" (defects that occur during the process) in the larger materials, which results in the creation of a final product that has better electrical properties (35.8 percent), better thermal properties (31.6 percent) and higher tensile strength (from 940 megapascals on average to 1080 MPa.)

The researchers believe their process paves the way for the creation of real world useful materials made with graphene such as those that could be used in managing heat in electronics in high power applications , or by allowing for the creation of composite materials with superior attributes, energy storage and new or better sensors and/or membranes. They also plan to continue their work with the process, hoping to better understand the structure of the fiber they create and hopefully to refine it even further to allow for the creation of a material that retains even more of 2D graphene's positive attributes.

More information: Highly thermally conductive and mechanically strong graphene fibers Science 4 September 2015: Vol. 349 no. 6252 pp. 1083-1087 DOI: 10.1126/science.aaa6502

ABSTRACT

Graphene, a single layer of carbon atoms bonded in a hexagonal lattice, is the thinnest, strongest, and stiffest known material and an excellent conductor of heat and electricity. However, these superior properties have yet to be realized for graphene-derived macroscopic structures such as graphene fibers. We report the fabrication of graphene fibers with high thermal and electrical conductivity and enhanced mechanical strength. The inner fiber structure consists of large-sized graphene sheets forming a highly ordered arrangement intercalated with small-sized graphene sheets filling the space and microvoids. The graphene fibers exhibit a submicrometer crystallite domain size through high-temperature treatment, achieving an enhanced thermal conductivity up to 1290 watts per meter per kelvin. The tensile strength of the graphene fiber reaches 1080 megapascals.

Journal information: Science

© 2015 Phys.org