June 19, 2015 report

New development technique requires less energy to create nanofilms (w/ Video)

A trio of researchers working at Imperial College in London has created a new development technique for constructing nanofilms that not only requires less energy but results in a product that is able to stand up to organic solvents. In their paper published in the journal Science, Santanu Karan, Zhiwei Jiang and Andrew Livingston describe their new process and the uses to which it might be put. Viatcheslav Freger of the Technion-Israel Institute of Technology, describes the work done by the team in a Perspective piece in the same journal issue, highlighting the two main innovations the team developed.

As Freger notes, separating molecules out of materials as part of developing products is an expensive part of product development—oftentimes it requires applying heat as part of an evaporative technique—a cheaper alternative would be filters, but attempts at developing them for many applications has been hindered by harshness of solvents. In this new effort, the researchers describe a technique they have developed that allows for the creation of nanofilms that are twice as permeable as those currently in use and have the added benefit of more surface area and are stronger to boot.

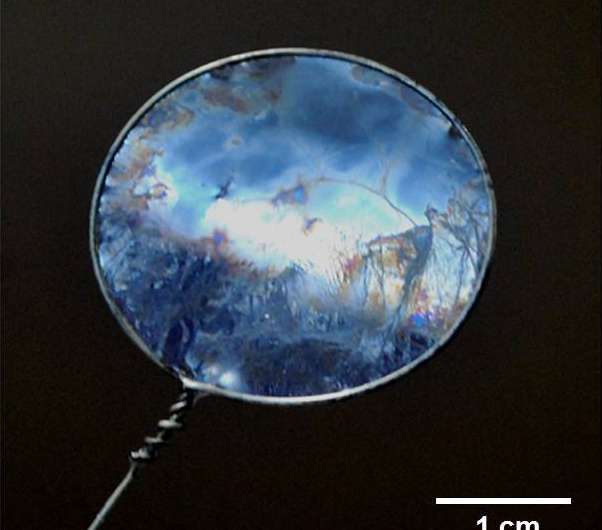

The membranes developed by the team were created using a modified version of interfacial polymerization where a sacrificial layer was used to help support the mix and treat the film (one of the innovations they added). They started by synthesizing a membrane of m-phenylenediamine-trimesoyl chloride that had terminal carboxylic acid groups on one side. That material was then layered onto another membrane that had a crumpled texture (their other innovation) which served to increase the surface area. They finished by exposing the film to a swelling solvent to increase its porosity. The result was a 10 nanometers thick membrane (on the same scale as cell membranes) capable of filtering molecules as part of a production process. Testing showed the membrane able to filter 112 liters of solvent per square meter per hour per bar of pressure, which is approximately twice the ability of membranes currently being used.

The team believes their new technique could be used in many chemical processes and should result in significant savings for product development.

More information: Science 19 June 2015: Vol. 348 no. 6241 pp. 1347-1351. DOI: 10.1126/science.aaa5058

Journal information: Science

© 2015 Phys.org