Multimode algorithm helps to get a better handle on tool deterioration

Computer numerically controlled (CNC) milling machines—used in high-tech industries such as aeronautical manufacturing—operate continuously to maximize the production efficiency. However, this requires careful monitoring for any tool deterioration. Omid Geramifard and co-workers from the Singapore Institute of Manufacturing Technology at A*STAR have now developed an improved algorithm for diagnosing tool-wear problems before they occur.

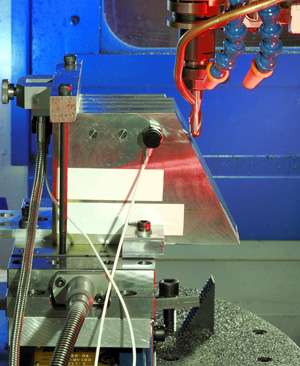

CNC milling machines cut and shave metal materials into precisely specified structures. To ensure they can operate 24 hours a day without any unnecessary downtime, the milling tools are carefully monitored with unobtrusive sensors and analytical computer models. The algorithm developed by Geramifard's team uses a sophisticated, multicomponent model that narrows down tool sensor data to the most effective group for analysis—an innovation that boosts its predictive capabilities while maintaining its computational efficiency.

As it is hard to estimate when tools will fail by simply using physical models of actual milling machines, researchers tend to use data-driven models that analyze historical tool-wear patterns. One such method, known as the hidden Markov model (HMM), hypothesizes that a tool's condition depends only on its past behavior, a simplification known as the Markov assumption. 'Hidden' states are then introduced to account for degradation factors that cannot be inspected directly. Using probability equations to relate observable data to the hidden states, HMMs can calculate how tools change over time.

Geramifard and co-workers improved current models by developing a multimode HMM-based approach that captures and analyzes several different tool-wear parameters. They 'trained' each mode of the HMM with selected segments of experimental data, and then combined the multiple outputs using weighting schemes. However, running simultaneous HMMs requires intense computational power, which significantly slows the CNC machine monitoring process.

To overcome this problem, the researchers devised a 'windowing' technique that reduces the computational cost by performing HMM calculations over a short time frame—selected through a cross-validation process in the training phase—instead of over the full observation sequence. When the team used their multimodal approach to predict tool wear in a real CNC milling machine, they found their approach outperformed conventional techniques when appropriate window lengths were adopted. This breakthrough in accuracy was realized by removing unnecessary connections to old observations.

"This model opens the path to more effective stochastic modeling of tool wear and degradation," says Geramifard. "With more accurate, data-driven diagnostics and prediction, more efficient tool usage can occur for assured quality of the produced workpiece."

More information: Geramifard, O., Xu, J.-X., Zhou, J.-H. & Li, X. Multimodal hidden Markov model-based approach for tool wear monitoring. IEEE Transactions on Industrial Electronics 61, 2900–2911 (2014). dx.doi.org/10.1109/TIE.2013.2274422