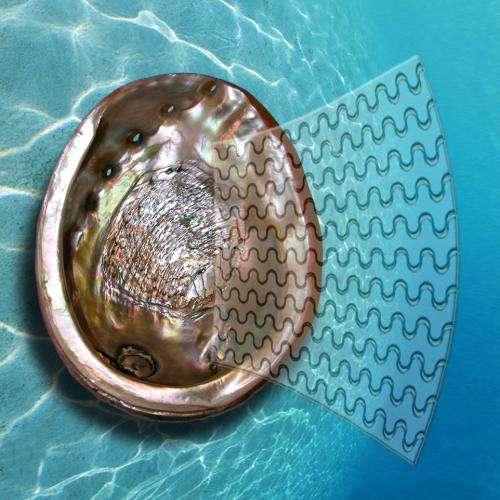

Mollusc shells inspire super-glass

Engineers intrigued by the toughness of mollusc shells, which are composed of brittle minerals, have found inspiration in their structure to make glass 200 times stronger than a standard pane.

Counter-intuitively, the glass is strengthened by introducing a network of microscopic cracks, according to a study published in the journal Nature Communications on Tuesday.

A team at McGill University in Montreal began their research with a close-up study of natural materials like mollusc shells, bone and nails which are astonishingly resilient despite being made of brittle minerals.

The secret lies in the fact that the minerals are bound together into a larger, tougher unit.

The binding means the shell contains abundant tiny fault lines called interfaces. Outwardly, this might seem a weakness, but in practice it is a masterful deflector of external pressure.

To take one example, the shiny, inner shell layer of some molluscs, known as nacre or mother of pearl, is some 3,000 times tougher than the minerals it is made of.

"Making a material tougher by introducing weak interfaces may seem counter-intuitive, but it appears to be a universal and powerful strategy in natural materials," the paper said.

Taking what they learnt, the team used a 3D laser to engrave microscopic fissures into glass slides, filled them with a polymer, and found it made them 200 times tougher.

The glass could absorb impacts better—yielding and bending slightly instead of shattering.

"A container made of standard glass will break and shatter if it is dropped on the floor.

"In contrast, a container made of our bio-inspired glass has the possibility to deform a little, without completely fracturing," study co-author Francois Barthelat told AFP.

"That container could therefore be used again after one or several drops."

The engraved glass can "stretch" by almost five percent before snapping—compared to a strain capacity of only 0.1 percent for standard glass.

The stronger glass may find application in bullet-proof windows, glasses, or even smartphone screens.

Glass is functional because of its transparency, hardness, resistance to chemicals and durability—but the main drawback is its brittleness.

The new method to address this weakness was "very economical," said Barthelat.

"All that is needed is a pulsed laser beam which can be accurately focused at pre-determined points.

"Our 3D laser engraving technique can easily be scaled up and applied to larger and thicker components of different shapes."

Previous attempts to copy the sturdy structure of mollusc shells had focused on creating new materials by assembling miniscule "building blocks"—like building a microscopic wall.

"Our idea was to attack the problem from a new angle: start with a large block of material with no initial microstructure and carve weaker interfaces within it," said Barthelat.

More information: Paper: dx.doi.org/10.1038/ncomms4166

Journal information: Nature Communications

© 2014 AFP