Better gold alloys for communications tech

(Phys.org) —Under the right circumstances, pushing on nothing is harder than pushing on something – at least when that "something" is gold. That's the finding from a new materials science paper, and it's a finding that could expedite the development of new wireless communication technologies.

The Problem

At issue are ohmic radio frequency microelectricalmechanical systems switches (RF-MEMS switches). That's an extremely long name for an extremely small object. RF-MEMS switches are basically just metal on-off switches. And they're tiny – only micrometers, or millionths of a meter, long. But they're key to the next generation of low-energy, wireless communication devices, such as satellites and cell phones.

But RF-MEMS switches can be unreliable, often breaking or getting stuck in the "on" position. And, as you can imagine, fixing micrometer-long switches in a cell phone is problematic – virtually impossible in a satellite.

"Solving the problem of reliability for RF-MEMS switches is a challenge due to the complex environment in which these switches have to operate," says Doug Irving, senior author of the paper and a materials science researcher at NC State. "We need a material that won't lose conductivity (when exposed to oxygen, due to oxidation, AKA rust), but that is strong enough to handle changes in current and temperature while being repeatedly flipped back and forth."

Gold meets most of these requirements. But gold is soft. If you push on it hard enough, or often enough, it will get bent out of shape – and your RF-MEMS switch won't work anymore.

So researchers have spent years trying to find out how to make a gold alloy that retains gold's good properties (like conductivity) but is hard enough to take a beating.

Most, if not all, of the researchers working on this problem have tested the hardness of their experimental gold alloys by pushing on them without running an electrical current through the probe they're pushing with. Remember that probe because, as it turns out, the lack of current makes a big difference.

The Study

This is where Doug Irving's research team comes in. Irving is a computational materials design expert. That means he develops complex computer models to see how a wide range of variables (e.g. heat or electricity) can influence how different materials behave.

And when the problem of gold alloys for RF-MEMS switches landed on his desk, he wanted to see if running an electrical current through the probe would make a difference. After all, these switches would only be operating when a current was being run through them.

Irving's team designed a model to evaluate the hardness of gold when the probe was running a constant voltage of 0.2 volts. (If that doesn't sound like much power, it's not. These are low-energy, remember?)

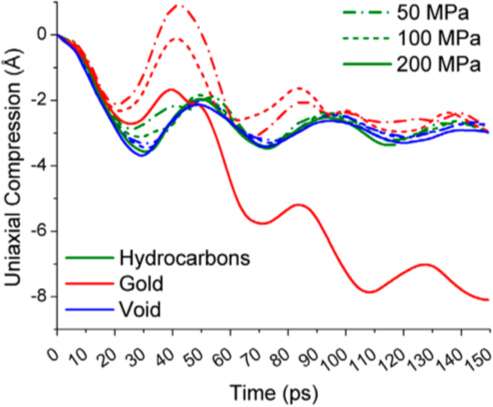

They then ran the model with the nanometers-wide probe making contact in three ways: with the probe flush against the gold surface; with the probe making contact with some gold, but also covering a "void" or empty gap in the surface (such voids are common at the nanometer scale); and with the probe making contact with some gold, but also covering a pocket of hydrocarbons (because these contaminants are also fairly common).

The researchers found that the gold became much softer when the probe was flush with the gold's surface, as opposed to when the probe covered a void or came into contact with hydrocarbons.

"Voltage leads to current, and current leads to heat," Irving says. "When the probe was flush with the gold's surface it conducted heat deep into the material, making it easier for the pressure of the probe to deform the metal. Hydrocarbons and empty space don't conduct current, so the current – and its related heat – spread out at the edges. The heat didn't extend much beyond the surface of the material."

To put this finding in context, Irving's team performed the same tests again, but without running 0.2V through the probe. In those tests, the gold was much harder when the probe was flush with the surface.

"Voltage makes a huge difference," Irving says. "This highlights the necessity for testing materials in 'in use' conditions, as close as possible to the conditions the material will face in its final application."

This doesn't solve the problem of finding the perfect alloy for RF-MEMS switches, but it does suggest better strategies. "And by incorporating current into the equation, we should find the right material much more quickly," Irving says.

And the sooner they find the right material, the sooner engineers can use that material to develop resilient RF-MEMS switches and related technologies.

More information: Christopher Freeze, Xiaoyin Ji, Angus Kingon. "Impact of Joule heating, roughness, and contaminants on the relative hardness of polycrystalline gold," Journal of Physics: Condensed Matter, 2013. DOI: 10.1088/0953-8984/25/47/472202

Provided by North Carolina State University