New chip provides better bioimaging performance

A microelectromechanical system developed in Singapore provides the 360-degree view that is critical in diagnostic imaging.

Small optical devices are important for diagnostic imaging in the body; they serve, for example, as optical probes in blood vessels or the gastrointestinal tract. For accurate diagnosis, such applications require a 360-degree view of their environment. A microelectromechanical silicon chip developed by researchers from the A*STAR Institute of Microelectronics, Singapore, in collaboration with colleagues from the National University of Singapore, offers a feasible solution for in vivo diagnostics. The chip can rotate scanning laser beams by almost a full turn at high speed.

Scientists are widely investigating the microelectromechanical systems (MEMS) used by the researchers in Singapore, with the aim of adding complex functionality to optical or mechanical applications. Typically, these systems are complex structures, such as movable parts or mirrors that are edged into a silicon chip. Their small size makes MEMS devices ideal for circumferential diagnostic imaging systems. The small scanning angles, however, limited earlier attempts to fabricate such devices. The difficulty arose from the inability to fully utilize standard MEMS-based actuators and their linear movements for rotational devices.

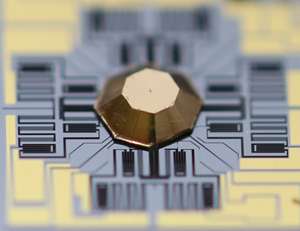

The important advance in the device's design is the implementation of a new reflector for the scanning laser, notes Xiaojing Mu from the research team. "We have designed a pyramidal polygon reflector as the key component to realize full circumferential scanning," says Mu. "The reflector is placed on a sophisticated structure that translates the linear movement of the electrostatic actuators into the large rotational motion of the reflector."

In the new design, the pyramidal reflector (see image) is mounted on a small ring. Four electrostatic actuators on the side of the device rotate this ring by about 40 degrees, which, combined with the eight facets of the pyramid, means that an almost full circumferential area is covered by a laser illuminating the pyramid. Because the actuators only use electrical fields to create movement via electrostatic repulsion, almost no electrical current is used. As such, the device consumes very little power and generates no heat, which makes it compatible for medical applications inside the body.

Although the present design represents a strong demonstration of the operating principle, further improvements will be needed, according to Mu. "Unfortunately, so far, the pyramidal polygon cannot be fabricated by the traditional MEMS semiconductor process. Thus, we are seeking alternative production strategies." Nevertheless, with the help of MEMS or even smaller devices on the nanoscale, there is increasing potential for realizing more sophisticated medical diagnostics for use in the human body.

More information: Mu, X., Zhou, G., Yu, H., Tsai, J. M.-L., Neo, W. K. et al. Electrostatic micromachined resonating micro-scanner for circumferential endoscopic bio-imaging. IEEE Photonics Technology Letters 25, 749–752 (2013).