Air bubbles could be the secret to artificial skin

(Phys.org) —Using foam substrates, EPFL scientists were able to make a flexible electronic circuit board. This discovery could lead to the creation of deformable and stretchable circuits.

How can you turn a material that is essentially rigid and breakable into something that can flex and bend? This is the problem that Stéphanie Lacour, Professor of the Bertarelli Foundation Chair at EPFL, is currently working on. Her goal is to be able to make circuit boards that are flexible enough to be integrated into artificial skin. Connected to the nervous system, these electronic circuits could become a true sense organ, allowing people to experience touches, tickles, and pain.

Lacour recently made a major step forward in her research, which has recently been published in the journal Advanced Materials. In experiments using various deformable materials, her team discovered a new kind of platform upon which to build circuits: elastomeric foams. These foams are used in packaging materials and products such as shoes, mattresses and bandages. Her team showed that a metallic film placed on a polyurethane foam substrate can be stretched in a reversible manner, without disrupting its electrical conductivity properties.

"Up to now, to find an appropriate substrate, we mainly worked on full and uniform elastomers," she explains. "Now, we're exploring new kinds of flexible, but heterogeneous, substrates in the form of foams. A more or less dense network of air bubbles inserted in an elastic matrix lets us modulate the elasticity of the substrate."

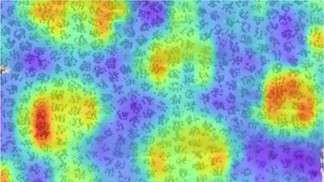

Localized cracks

On a uniform elastomeric substrate, traction tests revealed the creation of micro-fissures in the metallic layer, which would eventually result in the rupture of the conducting network. But with foam substrates, these cracks only occurred above the air bubbles. "Between the bubbles, the metal remained intact. The conducting network is thus maintained and can function," she explains. "Our measurements showed that we could achieve a level of elasticity over 100% without disrupting the network. These metallic pathways built upon foam could thus be used as electrodes, sensors or interconnections for the electronic skin that we're developing."

At the same time that she's pursuing this area of research, Lacour is also planning to test the flexibility of other electronic materials on pliable foam as well as various commercially available foams, with the objective of developing an electronic circuit board that is as flexible as "natural" skin.

Journal information: Advanced Materials

Provided by Ecole Polytechnique Federale de Lausanne