Scientists use 3-D printing to track big fish

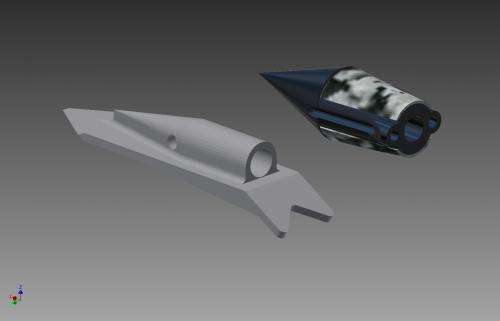

CSIRO scientists are using 3D printing to build a new generation of hi-tech fish tags made of titanium. The aim is to use the tags to track big fish such as marlin, tuna, swordfish, trevally and sharks for longer periods.

CSIRO is printing the tags at its 3D printing facility, Lab 22, in Melbourne. The tags are printed overnight and then shipped to Tasmania where marine scientists are trialing them.

Tags are made of titanium for several reasons: the metal is strong, resists the salty corrosiveness of the marine environment, and is biocompatible (non-toxic to living tissues).

One of the advantages of 3D printing is that it enables rapid manufacture of multiple design variations which can then be tested simultaneously. "Using our Arcam 3D printing machine, we've been able to re-design and make a series of modified tags within a week," says John Barnes, who leads CSIRO's research in titanium technologies.

"When our marine science colleagues asked us to help build a better fish tag, we were able to send them new prototypes before their next trip to sea," he adds.

CSIRO's 3D printing facility prints metal items layer by layer out of fused metal powder. Had the scientists been using conventional tags which are machined out of metal blocks, it would have taken a couple of months to design, manufacture and receive the new designs for testing.

"Our early trials showed that the textured surface worked well in improving retention of the tag, but we need to fine-tune the design of the tag tip to make sure that it pierces the fish skin as easily as possible," says John.

"The fast turnaround speeds up the design process – it's very easy to incorporate amendments to designs. 3D printing enables very fast testing of new product designs, which why it's so attractive to manufacturers wanting to trial new products."

Scientists from a number of agencies, including CSIRO Marine and Atmospheric Research, use fish tags to track movements of individual marine species and increase understanding of their behavior. Tracks of selected marine animals tagged by CSIRO and partner agencies can be viewed on the CSIRO Ocean Tracks website.

Medical implants such as dental implants and hip joints are made of biocompatible titanium with a surface texturing which speeds healing and tissue attachment after implantation. Scientists hope that a similar rough surface will help the tag to stay in fish longer.

"A streamlined tag that easily penetrates the fish's skin, but has improved longevity because it integrates with muscle and cartilage, would be of great interest to our colleagues conducting tagging programs across the world," said CSIRO marine researcher, Russell Bradford.

CSIRO's Lab 22 3D printing facility was established in October 2012 and has been used to manufacture a range of prototype products including biomedical implants, automotive, chemical processing and aerospace parts.

More information: To see videos and further information on CSIRO's research on 3D printing go to www.csiro.au/TitaniumTechnologies

To see tracks of tagged fish and 3D animations of fish in their underwater environment go to www.oceantracks.csiro.au/

Provided by CSIRO