August 9, 2012 feature

Graphene coating transforms fragile aerogels into superelastic materials

(Phys.org) -- Like donning a Superman’s cape, fragile carbon nanotube (CNT) aerogels that are covered by a graphene coating can be transformed from a material that easily collapses under compression to one that can resist large amounts of compression and completely recover its original shape after removal of the load. The superelasticity and fatigue resistance provided by the graphene coating could make CNT aerogels useful in a variety of areas, including as electrodes, artificial muscles, and other mechanical structures.

The researchers, Kyu Hun Kim, Youngseok Oh, and Mohammad F. Islam at Carnegie Mellon University in Pittsburgh, Pennsylvania, have published their paper on the mechanical benefits of a graphene coating on CNT aerogels in a recent issue of Nature Nanotechnology.

"We demonstrate the transformation of a nanotube network from fragile to superelastic simply via ‘nanocoating,’" Islam told Phys.org. "Typically, coating adds corrosion resistance, lubrication, aesthetics, alteration of surface chemistry, sealing, etc., but not mechanical property change."

While a normal gel consists mostly of liquid material with a cross-linked network that gives it its solid-like structure, an aerogel is created by replacing the liquid material in a gel with a gas. Researchers do this by drying the original gel at a critical temperature. The resulting aerogel is a lightweight material made of 99.9% air by volume, yet one that is also dry, rigid, and strong like a solid.

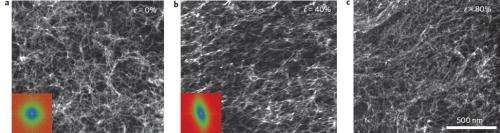

In the current study, the researchers worked with CNT aerogels, which (in addition to the air) are made of dispersed nanotubes about 1 micrometer long. CNT aerogels hold their shape due to molecular interactions at the nodes, the points where the nanotubes cross each other. However, when these aerogels are compressed by up to 90% of their original size, they collapse or become permanently deformed, limiting potential applications.

To overcome this inelasticity problem, the researchers demonstrated that one to five layers of graphene coating enables a CNT aerogel to withstand more than 1 million compressive cycles and return to its original shape after compression release. The ability to withstand this compression turns the aerogels into superelastic materials, while at the same time allowing them to maintain their other properties such as porosity and conductivity.

The researchers think that the graphene coating imparts this superelasticity to the aerogel by strengthening the aerogel’s nodes and struts, both of which support the aerogel’s network structure. In non-coated aerogels, the struts can bend and freely rotate about the nodes when compressed, which increases the contact area between nanotubes and forms new nodes. When the load is removed, the new nodes remain since more force is required to remove the nodes than to form them.

In contrast, the stronger struts in graphene-coated aerogels cannot easily rotate about the nodes when compressed. Although new nodes are formed in the coated aerogels as well, the graphene coating can remove these nodes when the load is removed.

“Both CNT aerogels and graphene-coated CNT aerogels form ‘new’ nodes when compressed,” Islam explained. “We think that the graphene at the nodes gets compressed and crumpled when the graphene-coated aerogels are compressed. When the load is removed, nanotube aerogels do not recover original shape because there is no restorative force to ‘break’ the new nodes that formed during compression. In contrast, the compressed and crumpled graphene flakes provide the restorative force (i.e., act as springs) that is needed to break these new nodes in graphene-coated aerogels.”

CNT aerogels that can undergo high levels of compression and later spring back to their original shapes could open the doors to new aerogel applications. CNT aerogels already have attractive features, such as the inherent flexibility of aerogel synthesis that allows researchers to control their shapes and sizes, and superelasticity makes these materials even more attractive.

“CNT aerogels, particularly single-walled carbon nanotube (SWCNT) aerogels, have a high surface area, are electrically conducting, have large pores, and have fairly good thermal dissipation properties if you consider that the amount of material in them is really small,” Islam said, adding that his team has recently published papers on the aerogels’ heat transport properties and a surface area close to the theoretical limit. “Because of their properties, CNT aerogels can be used as a scaffold to make composites, sieves, ultralight heat sinks in high gravity applications, electrodes, and catalyst supports. Typically, nanotubes are incompatible with polymers and tend to phase-segregate. By using aerogels as a scaffold and backfilling with polymer, nanotubes can remain well-dispersed in the polymer matrix. This can significantly improve mechanical enhancement.”

The researchers are currently investigating other areas of CNT aerogels, in addition to superelasticity.

“We are currently working on a few projects,” he said. “We are using SWCNT aerogels to make electrically conducting composites. We are also looking into making mechanically strong polymer composites. With our collaborators, we are exploring the electrochemical properties of SWCNT aerogels. We are growing metal nanoparticles on these SWCNT aerogels for use as filters for remediation of harmful chemicals from water. Also we are using them as porous 3D conducting substrates for tissue growth.

“I think the modulus and strength of these nanotube aerogels need to be improved without decreasing the porosity. As you can imagine, the aerogels can be made significantly stronger by just increasing the volume fraction of nanotubes in them but this will reduce the porosity.”

More information: Kyu Hun Kim, et al. “Graphene coating makes carbon nanotube aerogels superelastic and resistant to fatigue.” Nature Nanotechnology. Advance Online Publication. DOI: 10.1038/NNANO.2012.118

Journal information: Nature Nanotechnology

Copyright 2012 Phys.org

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.