August 10, 2012 feature

Bendable battery and LED make up the first functional all-flexible electronic system

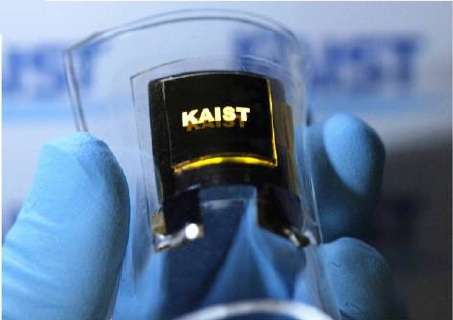

(Phys.org) -- By connecting a new flexible, thin-film Li-ion battery to a flexible organic LED, a team of researchers from South Korea has demonstrated the first fully functional all-flexible electronic system. In other words, they have shown the total integration of a flexible display and battery on a single plastic substrate without the help of bulk electronics. The achievement relies on a new fabrication method that enables flexible batteries to work with a variety of electrode materials, overcoming previous electrode limitations.

The researchers, from the Korea Advanced Institute of Science and Technology (KAIST) in Daejeon, South Korea, have published their study on the new bendable Li-ion battery in a recent issue of Nano Letters.

Although several other flexible Li-ion batteries have been developed already, none has achieved a sufficient performance in operation stability to be applied to commercial products, such as rollable displays and other flexible consumer electronics. The reason is that the electrodes for these batteries can only be made of a few materials due to fabrication difficulties, and these materials don’t have very good performance. As coauthor Keon Jae Lee of KAIST explains, one type of ideal cathode material would be a lithium transition metal oxide, although this is one of the materials that currently cannot be incorporated into bendable Li-ion batteries.

“Lithium transition metal oxides used as a cathode electrode have to be treated at high temperature (e.g., about 700 °C for lithium cobalt oxide) for the crystallinity,” Lee told Phys.org. “However, it is not possible to thermo-treat the active material on flexible substrates like polymer materials.”

To overcome this limitation, the researchers developed a fabrication technique that allows them to thermo-treat the electrode material, enabling the use of almost any material as an electrode. This technique, called the universal transfer method, involves originally depositing the battery materials onto a brittle mica substrate, similar to that used in standard non-flexible battery fabrication. Then, using sticky tape, the researchers peeled the mica substrate away, layer by layer. After about 10 minutes of peeling, the researchers could remove the entire mica substrate without damaging the thin-film battery.

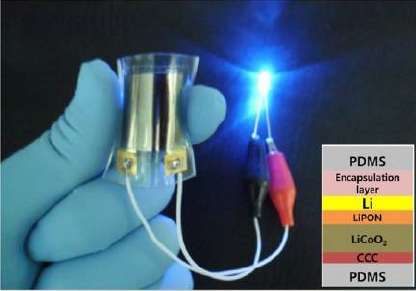

Next, the flexible battery is transferred onto a flexible polymer sheet and capped with another flexible polymer sheet. The result is a flexible Li-ion battery that can be made with almost any electrode material. Here, the researchers used lithium cobalt oxide as the cathode material, which is currently the most widely used cathode in non-flexible Li-ion batteries due to its high performance. For the anode, they used traditional lithium.

“We fabricated a high-performance flexible Li-ion battery structured with high-density inorganic thin films using the universal transfer approach, which enables the realization of diverse flexible Li-ion batteries regardless of electrode chemistry,” Lee said. “Moreover, it can form high-temperature annealed electrodes on polymer substrates for high-performance Li-ion batteries.”

In tests, the researchers demonstrated that the new flexible Li-ion battery has the highest charging voltage (4.2 V) and charging capacity (106 μAh/cm2) ever achieved for flexible Li-ion batteries. They also demonstrated that the battery could be bent with a high curvature angle. However, after 100 charge-discharge cycles, the battery lost some of its capacity. Depending on the degree of bending deformation, it maintained between 88.2% and 98.4% of its original capacity.

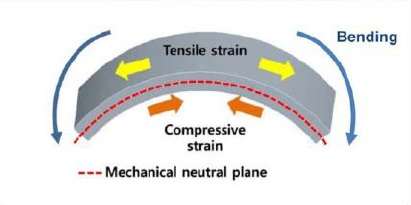

As the researchers explained, one tactic that helped them achieve this high performance even under a high curvature angle was placing the active parts of the battery in a mechanically neutral space within the battery film. When the battery film is bent, a counterbalance develops between the tensile strain on the outer side and the compressive strain on the inner side, which creates a mechanically neutral plane in the middle. Further, the researchers calculated that the point at which the compressive stress changes to tensile stress at a certain degree of bending may have even greater stability than on a brittle substrate. This finding suggests that it may be possible for flexible Li-ion batteries to have higher stability and better performance than non-flexible Li-ion batteries.

To fabricate the first fully functional all-flexible electronic system, the researchers connected the flexible Li-ion battery to a flexible organic LED, the latter of which was fabricated on a flexible indium tin oxide substrate. The researchers then wrapped the entire system with flexible polymer sheets to enhance the mechanical stability. They demonstrated that, even when the battery was in the bent position, it could still power the LED.

In the future, the researchers plan to improve the battery performance, particularly its energy density, as well as work on mass production through a one-step laser lift-off process instead of using sticky tape. They also note that the novel universal transfer method can be extended to fabricate other flexible devices, such as thin-film nanogenerators, thin-film transistors, and thermoelectric devices.

“I am interested in the combination of a flexible energy source and self-powered piezoelectric energy harvesting, called nanogenerators,” Lee said. “The fully flexible electronic system and its expansion with nanogenerators can be expected to change our daily life. Also, to be utilized in consumer electronics, increasing the power capacity is important. Therefore, 3D stacking of this 10-um-thick thin-film battery would be an interesting topic.”

More information: Min Koo, et al. “Bendable Inorganic Thin-Film Battery for Fully Flexible Electronic Systems.” Nano Letters. DOI: 10.1021/nl302254v

Journal information: Nano Letters

Copyright 2012 Phys.org

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.