Plasma startup creates high-energy light to make smaller microchips

A University of Washington lab has been working for more than a decade on fusion energy, harnessing the energy-generating mechanism of the sun. But in one of the twists of scientific discovery, on the way the researchers found a potential solution to a looming problem in the electronics industry.

To bring their solution to market two UW engineers have launched a startup, Zplasma, that aims to produce the high-energy light needed to etch the next generation of microchips.

"In order to get smaller feature sizes on silicon, the industry has to go to shorter wavelength light," said Uri Shumlak, a UW professor of aeronautics and astronautics. "We're able to produce that light with enough power that it can be used to manufacture microchips."

The UW beam lasts up to 1,000 times longer than competing technologies and provides more control over the million-degree plasma that produces the light.

For more than four decades the technology industry has kept up with Moore's Law, a prediction that the number of transistors on a computer chip will double every two years. This trend has allowed ever-smaller, faster, lighter and less energy-intensive electronics. But it's hit a roadblock: the 193-nanometer ultraviolet light now being used cannot etch circuits any smaller.

The industry has determined that the future standard for making microchips will be 13.5-nanometer light, a wavelength less than 1/14 the current size that should carry the industry for years to come. Such extreme ultraviolet light can be created only from plasmas, which are high-temperature, electrically charged gases in which electrons are stripped from their nuclei. The electronics industry is trying to produce this extreme ultraviolet light in various ways. One takes a droplet of tin and shoots it with a laser to make plasma that releases a brief spark of light. But so far this spark is too brief. Chip manufacturers use a $100 million machine to bounce light off a series of mirrors and eventually project the light onto a silicon wafer; each step absorbs some of the light's energy.

"Over the past decade, the primary issue with these extreme ultraviolet light sources is they just can't produce enough power," Shumlak said. "It's a stumbling block for the whole semiconductor industry."

Fusion scientists, it turns out, are plasma experts. The hydrogen plasma in the sun is so hot that hydrogen nuclei fuse together and release energy. Scientists around the world, including at the UW, are working to replicate this on Earth. A fusion reactor would use hydrogen as its fuel and emit helium as a waste product, a technically challenging

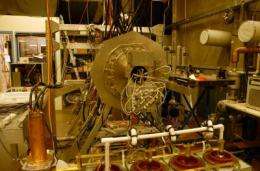

but clean source of energy. The UW group's specialty is a lower-cost version of a fusion reactor that uses currents flowing through the material, rather than giant magnets, to contain the million-degree plasma. Their method also produces plasma that is stable and long-lived.

"It's a completely different way to make the plasma that gives you much more control," said Brian Nelson, a UW research associate professor of electrical engineering.

The first time they triggered the experiment in 1999, an engineer looking through the glass said, "That was really bright!" That was when the proverbial light bulb went off, Nelson said, and the team began to explore applications for bright high-energy light.

They may have found that application in the microchip industry. Light produced through techniques now being considered by the chip industry generate a spark that lasts just 20 to 50 nanoseconds. Zplasma's light beam lasts 20 to 50 millionths of a second, about 1,000 times longer.

"That translates directly into more light output, more power depositing on the wafer, such that you can move it through in some reasonable amount of time," Shumlak said.

An initial grant from the UW's Center for Commercialization allowed the team to verify that it could produce 13.5-nanometer light. A gift last fall from the Washington Research Foundation helped the team shrink the equipment from the size of a broomstick to a new version the size of a pin, which can produce a sharp beam.

The company was established last year with help from the UW's Center for Commercialization and Henry Berg, a technology entrepreneur who met the researchers through the center's Entrepreneurs in Residence program. Berg is now CEO of Zplasma.

The company is seeking "smart money" from corporate investors who can integrate the new technology with existing industrial processes.

"I hope this gets implemented into the industry and has an impact," Shumlak said.

The group will continue its fusion research project funded by the U.S. Department of Energy. Raymond Golingo, a UW research scientist in aeronautics and astronautics, is co-author of the patent for the technology issued in 2008.

Provided by University of Washington