June 5, 2012 feature

Nanocones could be key to making inexpensive solar cells

(Phys.org) -- One of the biggest challenges facing the silicon photovoltaic industry is making solar cells that are economically viable. To meet this goal, the module cost, which is currently about $1/watt, needs to be decreased to just half that. Much of this cost comes from the silicon material and the expensive fabrication processes often used. In a new study, a team of scientists and engineers has demonstrated that a hybrid solar cell covered in silicon nanocones and a conductive organic polymer can address both cost-cutting areas while providing excellent performance.

The researchers, led by Professor Yi Cui and Professor Michael D. McGehee from Stanford University, have published their study in a recent issue of Nano Letters.

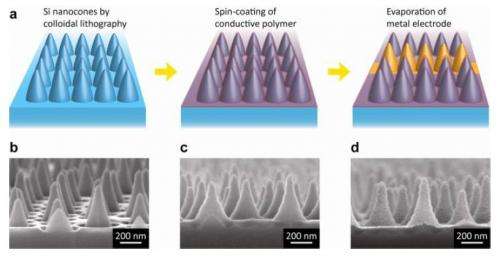

The hybrid solar cells’ use of nanoscale texturing has two advantages: it improves light absorption and reduces the amount of silicon material needed. Previous nanoscale texturing of solar cells has involved nanowires, nanodomes, and other structures. Here, the researchers found that a nanocone structure with an aspect ratio (height/diameter of a nanocone) of around one provides an optimal shape for light absorption enhancement because it enables both good antireflection (for short wavelengths of light) and light scattering (for long wavelengths).

In previous designs using nanoscale texturing, the space between structures has normally been too small to be filled with polymer, so a full second layer is required. But the tapered nanocone structure demonstrated here allows for the polymer to be coated in the open spaces, eliminating the need for other materials. By forming this nanocone/polymer hybrid structure with a simple, low-temperature method, processing costs are also reduced.

After testing the solar cell and making some improvements, the researchers produced a device with an efficiency of 11.1%, which is the highest among hybrid silicon/organic solar cells to date. In addition, the short-circuit current density, which indicates the largest current that the solar cell can generate, is only slightly lower than the world record for a monocrystalline silicon solar cell, and very close to the theoretical limit.

Due to the hybrid silicon nanocone-polymer solar cells’ good performance and inexpensive processing, the researchers predict that they could one day be used as economically viable photovoltaic devices.

More information: Sangmoo Jeong, et al. “Hybrid Silicon Nanocone-Polymer Solar Cells.” Nano Letters. DOI: 10.1021/nl300713x

Journal information: Nano Letters

Copyright 2012 Phys.org

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.