Cornell scientists review future of graphene

(PhysOrg.com) -- Graphene is sort of a scientific rock star, with countless groups studying its amazing electrical properties and tensile strength and dreaming up applications ranging from flat-panel screens to elevators in space.

The single-layer carbon sheets' stellar qualities are only just being understood in all their capacities, say scientists at Cornell -- and researchers can dream big (or rather, very small) when it comes to everything graphene can offer.

That's what scientists in the lab of Harold Craighead, the Charles W. Lake Professor of Engineering, say in an American Vacuum Society online review article, Sept. 9, about graphene's present and future. The article made the cover of the printed journal and quickly became one of its most-downloaded pieces.

"It's becoming clear that with modern fabrication techniques, you can imagine turning graphene into a technology," said Robert A. Barton, graduate student and lead author. "People often focus on the electronic applications of graphene, and they don't really think as much of its mechanical applications."

It's precisely this area where Cornell has produced some pioneering work. In particular the Craighead group, in collaboration with others including Jiwoong Park, assistant professor of chemistry and chemical biology, and Paul McEuen, the Goldwin Smith Professor of Physics, has used graphene in nanoelectromechanical systems (NEMS), analogous to an earlier generation's microelectromechanical systems (MEMS).

"We've moved beyond working with little exfoliated flakes and more with grown materials that can be incorporated and connected with electronics and other mechanics," Craighead said. "So the question is, can you make these reliably, uniformly and reproducibly?"

It was only a few years ago that scientists figured out how to make arrays of hundreds of thousands of graphene devices using a process called chemical vapor deposition. This involves growing the single-layer sheets of honeycomb-latticed carbon atoms on top of copper, then manipulating the graphene to make devices.

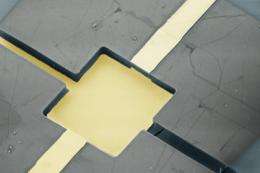

One of the Cornell researchers' devices is like a drum head -- a piece of graphene, one atom thick, suspended over a hollow well. Although growth of graphene by chemical vapor deposition on copper was invented elsewhere, Cornell researchers were the first to figure out how to make mechanical resonators from the large-area material.

"Four years ago we were able to make about one, and that took several months," Barton said. Speeding up the fabrication process has greatly increased graphene's potential in devices.

At Cornell, Barton and colleagues are working on making mass sensors out of graphene, which is atomically structured so it's sensitive to both mass and electric charge. What can result is that a bit of mass landing on a surface of suspended graphene will perturb the mechanical and electronic structure simultaneously, analogous to today's mass spectrometry but on a much smaller and more sensitive level, Barton explained.

The Cornell researchers are using optical interferometry to monitor the motion of a sheet of graphene. In this technique, the subtle device motions are read as variations in reflected light intensity, which are monitored by a fast photodiode connected to a spectrum analyzer. Another group at Cornell, led by McEuen, had earlier developed a way to "read out" carbon nanotubes, a technique that can also apply to graphene, Barton said.

The rapid progress of graphene makes its future very exciting, Craighead said.

"Graphene has gone from an oddity in a physics lab to something that can be practically incorporated into a variety of potential devices," he said. "The ability to fabricate things in these ways, to integrate them and to use them for different types of sensors, physical and chemical, is quite a step forward in a short time, and our group is one of the many that's contributed to this."

Provided by Cornell University