Ever-sharp urchin teeth may yield tools that never need honing

(PhysOrg.com) -- To survive in a tumultuous environment, sea urchins literally eat through stone, using their teeth to carve out nooks where the spiny creatures hide from predators and protect themselves from the crashing surf on the rocky shores and tide pools where they live.

The rock-boring behavior is astonishing, scientists agree, but what is truly remarkable is that, despite constant grinding and scraping on stone, urchin teeth never, ever get dull. The secret of their ever-sharp qualities has puzzled scientists for decades, but now a new report by scientists from the University of Wisconsin-Madison and their colleagues has peeled back the toothy mystery.

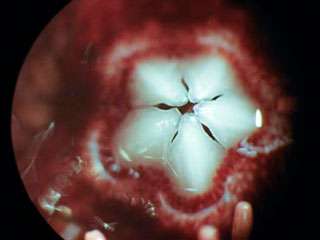

Writing today (Dec. 22, 2010) in the journal Advanced Functional Materials, a team led by UW-Madison professor of physics Pupa Gilbert describes the self-sharpening mechanism used by the California purple sea urchin to keep a razor-sharp edge on its choppers.

The urchin's self-sharpening trick, notes Gilbert, is something that could be mimicked by humans to make tools that never need honing.

"The sea urchin tooth is complicated in its design. It is one of the very few structures in nature that self-sharpen," says Gilbert, explaining that the sea urchin tooth, which is always growing, is a biomineral mosaic composed of calcite crystals with two forms — plates and fibers — arranged crosswise and cemented together with super-hard calcite nanocement. Between the crystals are layers of organic materials that are not as sturdy as the calcite crystals.

"The organic layers are the weak links in the chain," Gilbert explains. "There are breaking points at predetermined locations built into the teeth. It is a concept similar to perforated paper in the sense that the material breaks at these predetermined weak spots."

The crystalline nature of sea urchin dentition is, on the surface, different from other crystals found in nature. It lacks the obvious facets characteristic of familiar crystals, but at the very deepest levels the properties of crystals are evident in the orderly arrangement of the atoms that make up the biomineral mosaic teeth of the sea urchin.

To delve into the fundamental nature of the crystals that form sea urchin teeth, Gilbert and her colleagues used a variety of techniques from the materials scientist's toolbox. These include microscopy methods that depend on X-rays to illuminate how nanocrystals are arranged in teeth to make the sea urchins capable of grinding rock. Gilbert and her colleagues used these techniques to deduce how the crystals are organized and melded into a tough and durable biomineral.

Knowing the secret of the ever-sharp sea urchin tooth, says Gilbert, could one day have practical applications for human toolmakers. "Now that we know how it works, the knowledge could be used to develop methods to fabricate tools that could actually sharpen themselves with use," notes Gilbert. "The mechanism used by the urchin is the key. By shaping the object appropriately and using the same strategy the urchin employs, a tool with a self-sharpening edge could, in theory, be created."

Provided by University of Wisconsin-Madison