Chip provides its own power

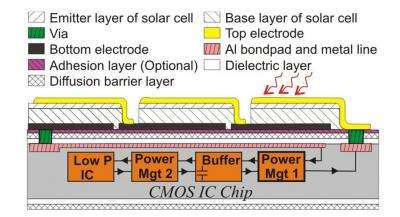

Microchips that 'harvest' the energy they need from their own surroundings, without depending on batteries or mains electricity. That will be possible now that Dutch researchers from the University of Twente's MESA+ Institute for Nanotechnology, together with colleagues from the universities of Nankai (China) and Utrecht, have for the first time succeeded in manufacturing a microchip with an efficient solar cell placed on top of the microelectronics.

The researchers presented their findings at the International Electron Device Meeting that was held from 5 to 8 December in San Francisco.

The placement of a solar cell directly on top of the electronics means the autonomous chip does not need batteries. In this way, for example, a sensor chip can be produced, complete with the necessary intelligence and even an antenna for wireless communication. However, the chip's energy use must be well below 1 milliwatt, say the researchers. The chip can then even collect enough energy to operate indoors.

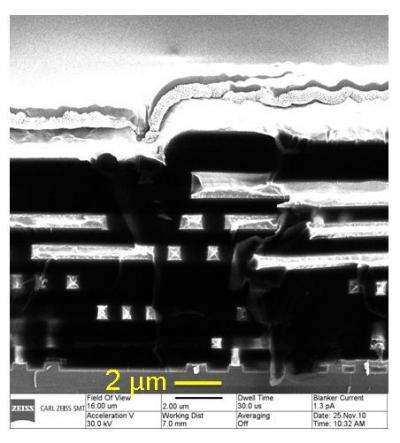

The simplest solution would seem to be to manufacture the solar cell separately and then fit it on top of the electronics, but this is not the most efficient production process, so instead the researchers use the chip as a base and apply the solar cell to it layer by layer. This uses fewer materials, and also ultimately performs better. But the combination is not trouble-free: there is a risk that the steps in the production of the solar cell will damage the electronics so that they function less efficiently.

For this reason the researchers decided to use solar cells made of amorphous silicon or CIGS (copper - indium - gallium - selenide). The manufacturing procedure for these cells does not influence the electronics, and these types of solar cells also produce sufficient power, even in low light. Tests have shown that the electronics and the solar cells function properly, and the manufacturing process is also highly suitable for industrial serial production with the use of standard processes.

The research was carried out in the Semiconductor Components group led by Prof. Jurriaan Schmitz. The researchers collaborated with colleagues from Nankai University in Tianjin, China and the Debye Institute of Utrecht University. The research was made possible by the STW Technology Foundation.

More information: The paper 'Above-CMOS a-Si and CIGS Solar Cells for Powering Autonomous Microsystems' by J. Lu, W. Liu, C.H.M. van der Werf, A.Y. Kovalgin, Y. Sun, R.E.I. Schropp and J. Schmitz was presented at the International Electron Device Meeting in San Francisco.

Provided by University of Twente