This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

New system enhances mechanical stability of nanofiber-based bioelectrodes

Flexible electronic devices based on electrospun nanofiber membranes (ENM) are attracting significant attention due to their high biocompatibility and excellent mechanical performance. However, patterning conductive materials on fiber substrates typically requires expensive vacuum equipment or additional processes to create separate masks.

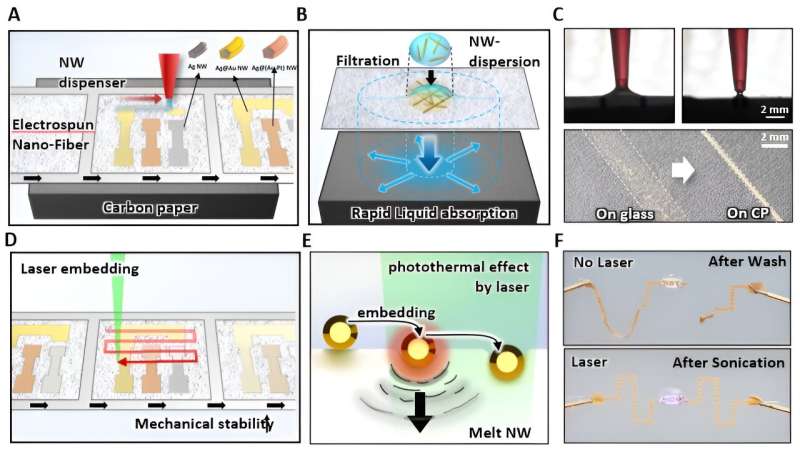

To address this, a collaborative research team led by Professor Seung Hwan Ko of the Department of Mechanical Engineering at Seoul National University and Professor C-Yoon Kim of Konkuk University developed a system that induces efficient fluid flow using capillary action by placing a carbon paper support under the nanofiber membrane, enabling the filtration process without the need for vacuum equipment.

The research was published in Advanced Functional Materials on May 29.

This approach enhances mechanical stability by strongly bonding nanowires and substrates through the photothermal effects of lasers during the post-processing stage. In addition, the system demonstrated that circuits remained stable even under strong ultrasonic treatment and that the patterns on the substrate remained intact when manually pulled.

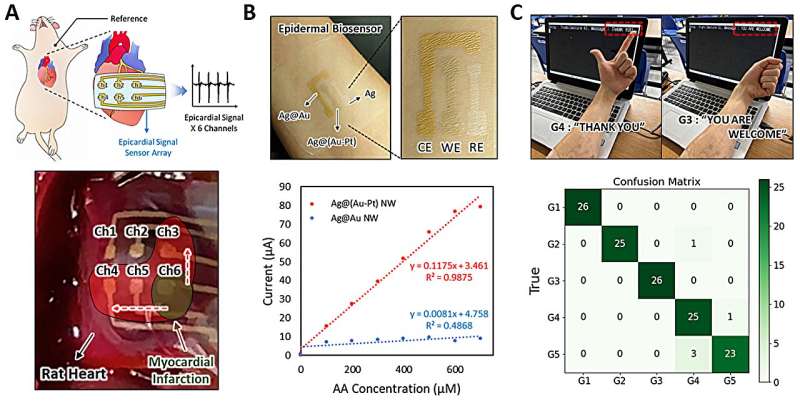

The team validated the strengths of their developed process system and outcomes through various applications, including an in vivo epicardial signal recording ECG electrode, an epidermal electrochemical biosensor, and customized epidermal electromyography (EMG)-based human–machine interface (HMI).

The potential of the electrospun nanofiber membrane (ENM)-based soft electronics in epidermal bioelectronics has gained huge attention with their conformal compatibility with the human body and associated performance improvements.

However, patterning conductive materials on fiber substrates typically requires expensive vacuum equipment or additional processes to create separate masks.

The research team developed a system that enables the filtration process without the need for costly vacuum equipment by placing a carbon paper support under the nanofiber membrane, inducing efficient fluid flow through capillary action.

Using this system, the nanowires and substrates can be strongly bonded through the photothermal effects of lasers during the post-processing stage, enhancing mechanical stability. The system also demonstrated that circuits remained stable under strong ultrasonic treatment and that the patterns on the substrate remained intact when manually pulled.

The research team validated the strengths of their developed process system and outcomes through various applications, including an in vivo epicardial signal recording ECG electrode, an epidermal electrochemical biosensor, and customized epidermal electromyography (EMG)-based human–machine interface (HMI).

Additionally, this research has opened up possibilities for efficiently fabricating electronic devices with high stretchability, breathability, and conductivity, demonstrating potential applications in various health care and medical fields.

More information: Hyeokjun Yoon et al, Adaptive Epidermal Bioelectronics by Highly Breathable and Stretchable Metal Nanowire Bioelectrodes on Electrospun Nanofiber Membrane, Advanced Functional Materials (2024). DOI: 10.1002/adfm.202313504

Journal information: Advanced Functional Materials

Provided by Seoul National University College of Engineering