This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Using machine learning to optimize volatile fatty acid production in riboflavin-mediated sludge fermentation

Waste activated sludge (WAS) is the most yielding byproduct in municipal wastewater treatment plants (MWTPs), and its disposal poses secondary pollution that severely threatens the environment. Producing volatile fatty acids (VFAs) from WAS is a promising technology that enables the reutilization of organic carbons associated with the WAS complex.

Additionally, VFAs can favor the downstream synthesis of bio-degradable plastics and the removal of nutrients in MWTPs in laboratory-scale, pilot-scale, and full-scale applications. However, VFA fermentation is a complex and tedious process, and using alkaline, ultrasonic, and thermal pretreatments promotes VFA production; they are energy-consuming and uneconomic, limiting their large-scale engineering applications.

The researchers noted that the production of fermentative VFAs could be enhanced by the use of chemical redox mediators, especially riboflavin, which is an affordable and eco-friendly redox mediator. However, the process is highly complicated, affected by various environmental factors, intermediates, and process conditions.

Although current single-factor experiments could unveil the preliminary response of individual driving factors for VFA production by time- and labor-consuming tests, it was impossible to reveal their interactions. Also, it could not optimize the multiple operating conditions for maximum VFA production from WAS.

To optimize this complex fermentation process, researchers explored the application of machine learning (ML). Unlike mathematical models, ML models are independent of biological processes and intrinsic mechanisms and can predict the concerning targets and extract and identify the feature importance of different variables.

Although ML models have been used to develop robust data-driven soft sensors to predict VFA production from anaerobic digestion systems, few attempts considered the interactive effects among various input variables that would determine the ideal output and optimal process conditions.

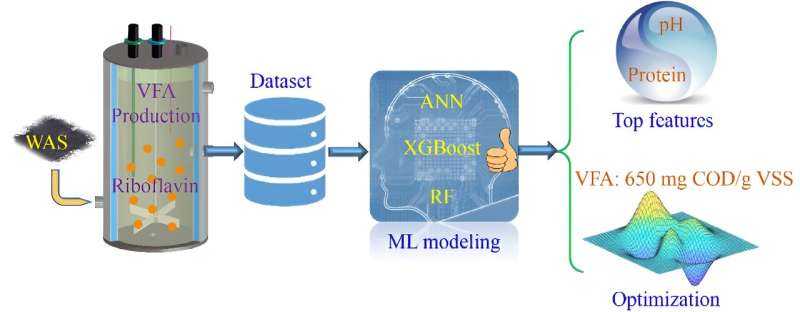

In consequence, to develop a cost-effective ML model for predicting VFA production from riboflavin-mediated WAS fermentation systems, the research team from Hangzhou Dianzi University tested ANN, XGBoost, and RF. This study entitled "Machine learning enabled prediction and process optimization of VFA production from riboflavin-mediated sludge fermentation" is published online in Frontiers of Environmental Science & Engineering.

Considering the input variables (pH, temperature, fermentation time, soluble protein, total carbohydrates, reducing sugar, NH4+–N and riboflavin dosage), output variable (VFA production), and microbial community, the experimental data were obtained from previous studies.

In this study, the importance of input variables in predicting VFA production was analyzed and ranked based on optimal ML models. In addition, optimization algorithms were applied to predict the maximum VFA production and the corresponding process conditions.

Their results showed that among the three tested ML algorithms, eXtreme Gradient Boosting (XGBoost) presented the best prediction performance and excellent generalization ability, with the highest testing coefficient of determination (R2 of 0.93) and lowest root mean square error (RMSE of 0.070).

The Shepley Additive Explanations (SHAP) method was also used to analyze feature importance and their interaction, pH, and soluble protein were found to be the top two input features in the modeling. Using genetic algorithm (GA) and particle swarm optimization (PSO), the study found the optimal solution of VFA output, and the predicted maximum VFA output was 650 mg COD/g VSS.

These results provided a data-driven approach to predict and optimize VFA production from riboflavin-mediated WAS fermentation. By combining chemical treatment and machine learning, researchers have not only succeeded in improving the production efficiency of VFAs, but also opened up new possibilities for the sustainable management of waste-activated sludge.

This progress is expected to play a key role in environmental protection and resource recovery, bringing a positive impact on urban sewage treatment in the future.

More information: Weishuai Li et al, Machine learning enabled prediction and process optimization of VFA production from riboflavin-mediated sludge fermentation, Frontiers of Environmental Science & Engineering (2023). DOI: 10.1007/s11783-023-1735-8

Provided by Higher Education Press