This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Fermentation processes for the production of biohydrogen as an alternative energy carrier

Hydrogen is considered a clean and efficient energy carrier that will have broad applications in the future—as a fuel for cars, buses, for houses heating, or as an energy storage. However, it is currently mainly produced from fossil fuels. In order for it to become a "green" energy carrier, techniques for extracting it from renewable sources such as solar energy, wind, water, or biomass must be developed.

Lignocellulosic biomass hydrolysates rich in sugars can be used by bacteria to produce hydrogen in the dark fermentation process. The use of biomass in these processes serves a has a dual function—waste reduction with simultaneous energy production. However, these processes still require optimization to become economically viable.

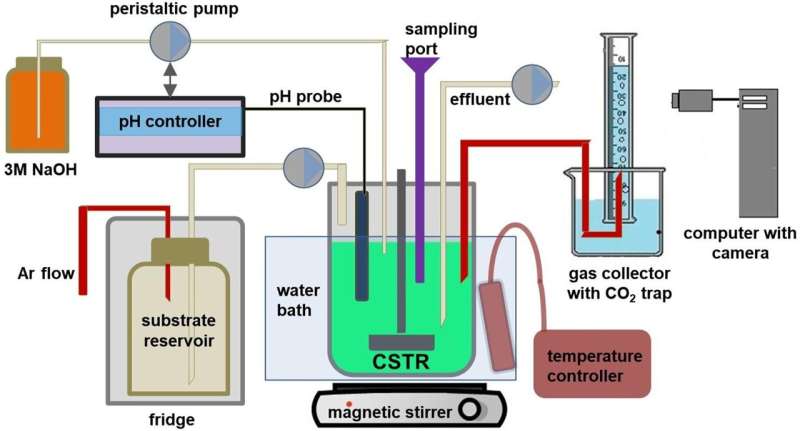

In an article published in Bioresource Technology by Dr. Zagrodnik from the Department of Chemical Technology at the Faculty of Chemistry of Adam Mickiewicz University, the results of research aimed at understanding the effect of hydraulic retention time and pH conditions on the process of hydrogen production in a continuous bioreactor were described. This allowed the investigation of the mutual dependencies between these parameters. Cellobiose, xylose, and arabinose were used as substrates, which are sugars frequently found in lignocellulosic hydrolysates.

The process was carried out using a mixed bacterial culture to enable the simultaneous utilization of different substrates. An increase in hydrogen production rate was observed at shortened hydraulic retention time. Moreover, it was demonstrated that optimal pH conditions depend on the hydraulic retention time.

The research showed that a mixture of sugars imitating lignocellulosic hydrolysates can be successfully used during dark fermentation with high hydrogen production rates at pH 6.0 and 6.5. Lower hydrogen production rates at pH 5.0 mainly resulted from the low degree of utilization of arabinose.

Additionally, it was shown that, unlike hydraulic retention time, pH conditions had a significant impact on the bacterial culture composition. Clostridium beijerinckii and Clostridium guangxiense were the dominant microorganisms.

The obtained results will enable the implementation of biological methods for hydrogen production on a larger scale.

More information: Roman Zagrodnik et al, Dark-fermentative hydrogen production from synthetic lignocellulose hydrolysate by a mixed bacterial culture: The relationship between hydraulic retention time and pH conditions, Bioresource Technology (2022). DOI: 10.1016/j.biortech.2022.127309

Journal information: Bioresource Technology

Provided by Adam Mickiewicz University