This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Multimodal graphene-based e-textiles for the realization of customized e-textiles developed for the first time

A joint research team led by Principal Researcher Soongeun Kwon and Professor Young-Jin Kim has developed graphene-based, customized e-textiles, for the first time in the world. They published their findings in ACS Nano in a paper titled, "Multimodal E-Textile Enabled by One-Step Maskless Patterning of Femtosecond-Laser-Induced Graphene on Nonwoven, Knit, and Woven Textiles."

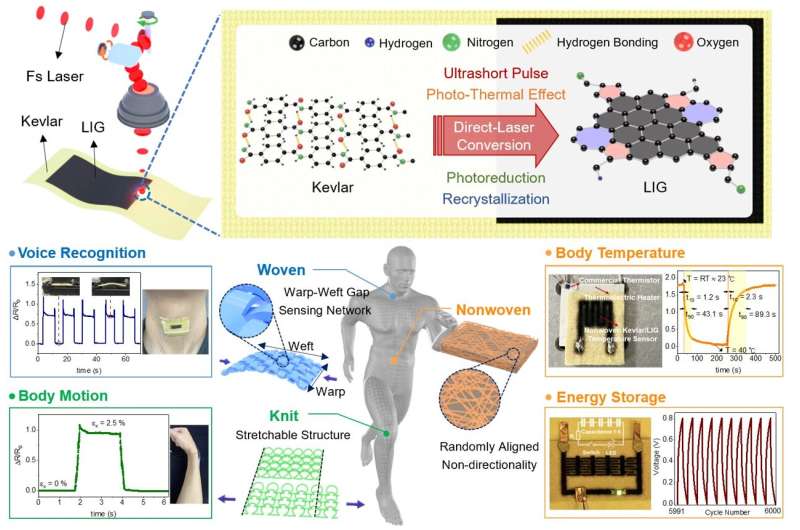

Instead of using toxic chemicals or optical masks for patterning, the joint research team used laser direct patterning technology to form laser-induced graphene (LIG) on e-textiles and successfully manufactured graphene-based e-textiles.

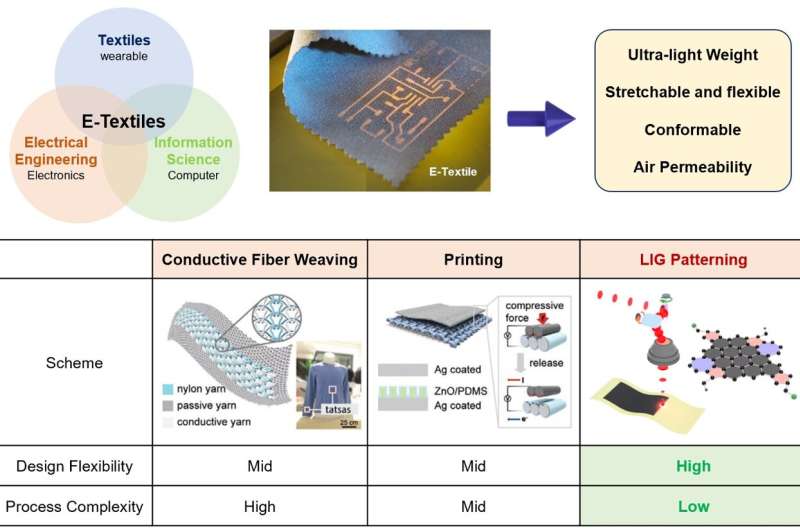

Conventionally, e-textiles have been manufactured by coating fabrics with conductive ink to make electrically conductive textiles and then weaving them with generic fabrics, or by attaching a thin, functional layer onto generic fabrics. These methods have a low design flexibility and high process complexity. Moreover, harmful chemicals may be leaked during the manufacturing process, which places a limitation on mass production.

By using the newly developed technology, high-quality LIG materials that have world-class electrical conductivity can be manufactured simply by irradiating laser onto the surface of fabrics.

A major advantage of this technology is that e-textiles can be manufactured in an environmentally friendly manner, as neither the use of chemicals nor any additional processing is required. Meanwhile, the world-class electrical conductivity of LIG electrodes has been realized by applying the femtosecond laser processing technology.

The newly developed technology can be used in the future for manufacturing industrial and military clothes for personal health management and also for producing customized "smart" clothes in the health care sector.

Kwon said, "This technology has been developed by analyzing the structures of generic fabrics and realizing them as graphene-based materials that have advanced features of optimal e-textiles." He added, "This technology is significantly meaningful in that it allows for the mass production of customized e-textiles using an environment-friendly and simple method."

More information: Dongwook Yang et al, Multimodal E-Textile Enabled by One-Step Maskless Patterning of Femtosecond-Laser-Induced Graphene on Nonwoven, Knit, and Woven Textiles, ACS Nano (2023). DOI: 10.1021/acsnano.3c04120

Journal information: ACS Nano

Provided by Korea Institute of Science and Technology