This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Metamolecule metamaterial fabrication with 3D co-assembly

Metamaterials, famously likened to Harry Potter's invisible cloak, are artificial nano structures designed to manipulate light properties. However, the practical application of this technology in everyday life depends on the commercialization of the manufacturing process which requires significant costs.

A research team led by Professor Junsuk Rho from the Department of Mechanical Engineering and the Department of Chemical Engineering, researcher Won-Geun Kim and Ph.D. candidate Hongyoon Kim from the Department of Mechanical Engineering at Pohang University of Science and Technology (POSTECH) has devised an approach.

Their method combines three-dimensional nano printing with co-assembly technology, bringing metamaterials one step closer to becoming commercially available. These research findings have been featured in Small.

Traditionally, metamaterials are crafted by depositing physical and chemical layers onto materials such as silicon and resin (plastic), followed by a process called lithography. Regrettably, this method is both expensive and limited in terms of applicable materials. Consequently, the academic community has recently shifted its focus towards creating metamaterials through the assembly of particles rather than the costly process of surface shaving.

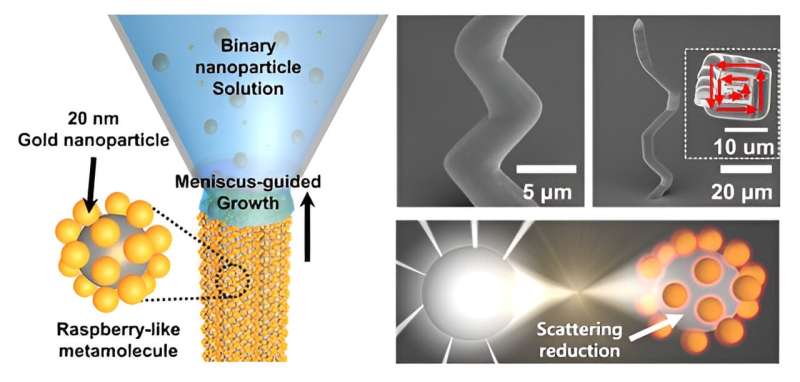

In this research, the research team employed a combination of three-dimensional nano printing and co-assembly techniques. Initially, they crafted raspberry-like metamolecules by using silica (glass) and gold nanoparticles of varying sizes. Subsequently, these raspberry-like structures were stacked atop one another, resulting in the successful creation of millimeter-sized metamaterials.

In essence, the research team has devised a process technology that enables the cost-effective production of metamaterials in desired shapes as opposed to conventional and more expensive methods.

The experiments conducted showcased the light-controlling capabilities of metamaterials generated through the team's process. Notably, there was a significant reduction in scattered light within the visible region. This research marks the first instance of verifying the optical properties of metamolecules in solution using the millimeter-sized structures.

This approach allows for results to be observed with the naked eye or through a simple microscope setup, eliminating the need for specialized equipment for verification. Additionally, the team achieved fine-tuned control over the optical properties by adjusting the ratio of silica and gold nanoparticles within the metamaterial.

Professor Junsuk Rho who led the research stated, "This breakthrough enables the design and implementation of free-form nanophotons, surpassing the limitations of existing metamaterial fabrication processes. The versatility of this technology affords a wide range of material choices including quantum dots, catalyst particles, and polymers, making it applicable to diverse fields from sensors to displays in addition to metamaterial research."

More information: Won‐Geun Kim et al, Freestanding, Freeform Metamolecule Fibers Tailoring Artificial Optical Magnetism, Small (2023). DOI: 10.1002/smll.202303749

Journal information: Small

Provided by Pohang University of Science and Technology