This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Easier and faster materials microstructure analysis through human-AI collaboration

A research team led by Dr. Se-Jong Kim and Dr. Juwon Na of the Materials Data Management Center in the Materials Digital Platform Division together with a research team led by Professor Seungchul Lee of POSTECH has developed a technology that can automatically identify and quantify materials microstructure from microscopic images through human-in-the-loop machine learning.

The research results were published on 15 August in Acta Materialia.

Microscopic imaging systems visualize material structure information at multiple levels, from the nanoscale to the mesoscale. Quantitative analysis of microstructure is the process of extracting structural statistics from microscopic images. However, due to the complexity and diversity of microstructure, there have been many limitations for humans or AI to perform this alone.

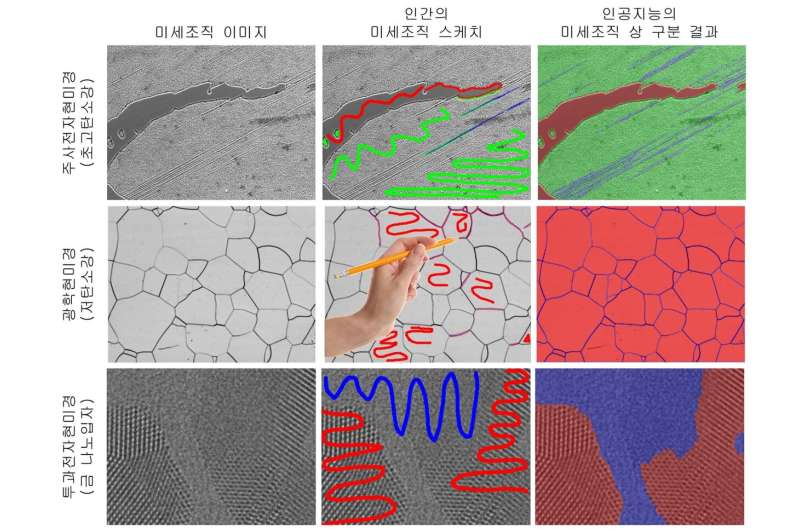

By effectively integrating human and AI capabilities, the research team has developed an integrated framework for quantitative microstructure analysis. This technology enables the AI to perform microstructure segmentation using only a single microstructure image and its corresponding scribble annotation by domain experts. In addition, the AI interacts with humans by actively requesting scribble annotation from experts in order to bring additional improvements in both the model's performance and reliability.

Through extensive experiments, the research team confirmed that the framework of human-AI collaboration is universal and can be applied to a wide range of materials, microstructures, and microscopic imaging systems.

While previous research has required the collection of large amounts of dense annotation, this study has greatly reduced annotation costs by replacing dense annotation with scribble annotation that can be easily drawn using a pen or mouse. This technology will be incorporated into the Automated Microstructure Quantitative Analysis System (TIMs) being developed by KIMS. This will make it easy for general researchers to use.

Dr. Juwon Na, a senior researcher at KIMS, said, "This study is the result of improving the existing subjective and time-consuming quantitative analysis of microstructure into an objective and automated process."

Professor Seungchul Lee of POSTECH, added, "Our framework that interacts with experts is expected to be widely used as a core analysis technology in industry and research, and through this, we expect to dramatically reduce the cost and time of new materials research and development and further significantly improve reliability."

More information: Juwon Na et al, A unified microstructure segmentation approach via human-in-the-loop machine learning, Acta Materialia (2023). DOI: 10.1016/j.actamat.2023.119086

Journal information: Acta Materialia

Provided by National Research Council of Science & Technology