This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Chemists develop next-generation self-healing plastic that's also biodegradable

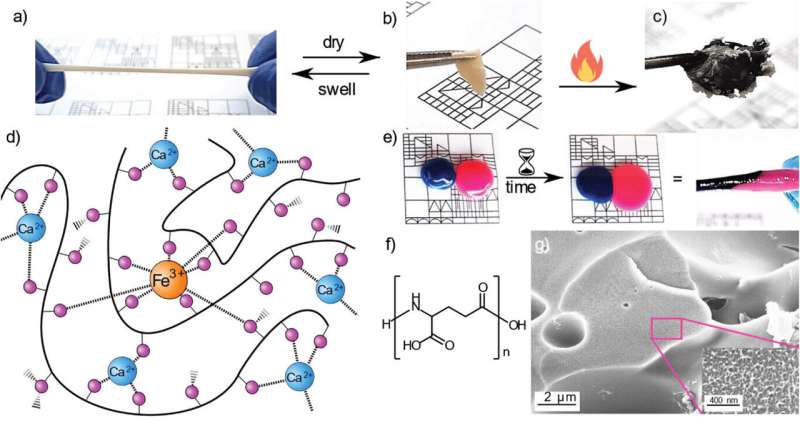

Imagine a plastic that is harder than common plastics, non-flammable, and even has self-healing properties. But that is not all—it can be produced at room temperature in water, which is very energy-efficient and does not require toxic solvents. Before hardening, you can shape the plastic in any way you want—like chewing gum. By adding water, it can also be converted back to its "chewing gum" form at any time, reshaped and thus recycled as often as desired.

In 2016, the research team around Konstanz chemist Helmut Cölfen presented just such a material—a mineral plastic. Even though the plastic, with its novel manufacturing process and outstanding material properties, has since attracted great interest from industry, it still had a crucial shortcoming from the Konstanz chemists' point of view: due to its chemical composition, it was difficult to biodegrade.

A new ingredient for greater environmental compatibility

"Previously, we used polyacrylic acid to produce our mineral plastic. Chemically, this acid has the same backbone as polyethylene, which is known to cause major problems in the environment because it is hardly biodegradable," explains Cölfen. The research team led by Cölfen and Ilesha Avasthi, a postdoc in Cölfen's lab, therefore set to work looking for an alternative basic building block to develop an environmentally compatible mineral plastic that retains the intriguing properties of the original material. And they found what they were looking for.

In their current publication in the journal Small Methods, the Konstanz chemists present the next generation of their mineral plastic. Instead of petroleum-based ingredients such as polyacrylic acid, they now use polyglutamic acid. This natural biopolymer is readily available in large quantities and can even be obtained sustainably, for example from biotechnological production using microorganisms. A variety of microorganisms that already exist in the environment can degrade polyglutamic acid.

"Our new mineral plastic has the same positive properties as the previous one, but has the decisive advantage that its basic building block—polyglutamic acid—can be produced with the help of microorganisms and is completely biodegradable," says Helmut Cölfen.

Support from biologists

In order to prove that this biodegradability also applies to the new mineral plastic itself and not just to its individual components, the chemists enlisted the support of David Schleheck and postdoc Harry Lerner from the Department of Biology at the University of Konstanz. "Helmut Cölfen has created a new type of mineral plastic in his laboratory, and our task now was to make it disappear again with the help of microorganisms," says Schleheck.

In degradation experiments, the biologists were able to show that microorganisms found in forest soils, for example, began metabolizing the mineral plastic after just a few days. After only 32 days, the microorganisms had completely degraded the plastic. So the researchers have actually succeeded in making the mineral plastic with all its positive material properties now also sustainable and biodegradable.

More information: Ilesha Avasthi et al, Biodegradable Mineral Plastics, Small Methods (2023). DOI: 10.1002/smtd.202300575

Journal information: Small Methods

Provided by University of Konstanz