June 22, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

A photonic-crystal surface-emitting laser built bright enough for industrial-scale cutting

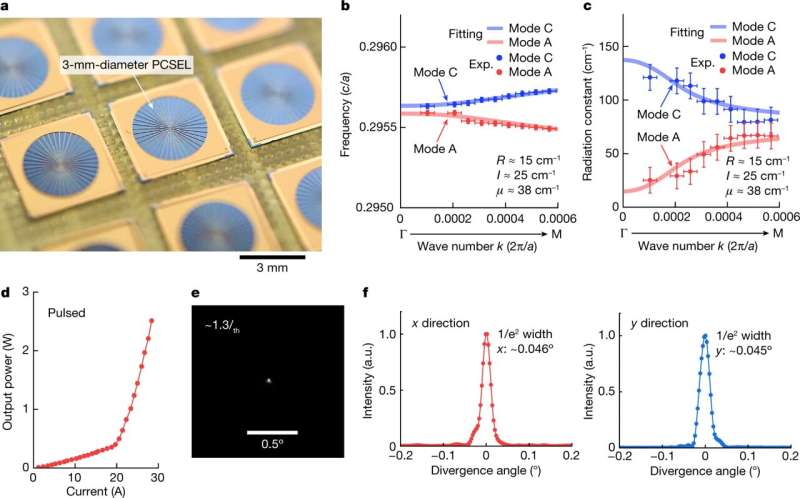

A team of photonics and electronic engineers at Kyoto University has found a way to overcome the shortcomings of photonic-crystal surface-emitting lasers (PCSELs) that have prevented their use in industrial-scale cutting applications. In their study reported in the journal Nature, the group made changes to traditional PCSELs to confer the brightness needed for such applications.

Currently, gas and solid-state lasers are used to cut materials in industrial scale applications, including steel. But users of such systems would prefer to use semiconductor lasers because they are far less bulky and energy intensive. Unfortunately, such lasers have not been suitable for such work due to beam quality issues related to many-mode oscillations and thermal destabilizing effects. In this new effort, the research team in Japan found a way to overcome these problems, allowing for the creation of PCSELs that can be used for industrial scale applications.

To overcome the problems, the engineers changed the structure of the PCSELs. One such change involved increasing the diameter size from 1 millimeter to 3 millimeters, allowing for up to 50 watts of power output. The increase in size resulted in an associated brightness increase to 1 GW/cm2/str—high enough for industrial applications.

Increasing the diameter size led to lateral oscillation problems, which was expected. Without correction, they lead to beam quality degradation, as can the increased heat that is generated. To overcome these problems, the team embedded photonic crystals in the laser and also modified the internal reflector layer. To embed the photonic crystals, the team designed a pattern of holes in a crystal layer to deflect light in useful ways, resulting in the creation of a beam with very little divergence.

To prevent oscillation problems, the team also adjusted the bottom layer of the PCSEL to increase loss of unwanted vertical modes. They altered the heat refractive index to reduce heat-induced problems by modifying the air holes in the photonic crystal. And they used nano-imprint lithography to make the photonic crystals, allowing for speedier production.

The researchers plan to continue scaling up their laser, hoping to bring the diameter to 10mm, which would allow for producing a 1-kilowatt beam.

More information: Masahiro Yoshida et al, High-brightness scalable continuous-wave single-mode photonic-crystal laser, Nature (2023). DOI: 10.1038/s41586-023-06059-8

Journal information: Nature

© 2023 Science X Network