April 4, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Adding a conductive copolymer improves efficiency of bacterial production of commercial polypeptide

A team of chemists at the Chinese Academy of Sciences' Institute of Chemistry has developed a process for dramatically improving the efficiency of bacterial production of a commercial polypeptide. Their paper is published in the journal Science Advances.

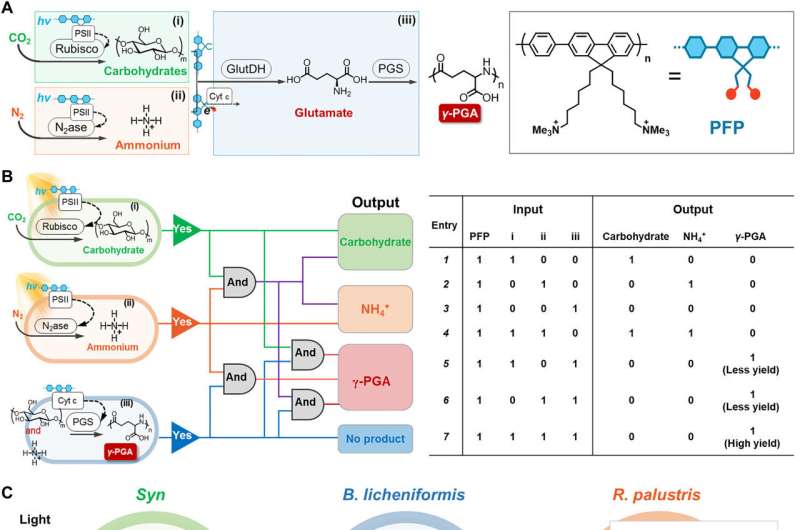

Microbes have been used to produce natural products for several decades, but in many cases, yields are too low for mass production. So chemists have been looking for ways to improve yields using symbiotic characteristics between microbes. In this new effort, the research team took advantage of different characteristics of three types of bacteria to create an environment that would produce a commercially desirable polypeptide—and then they added a conductive copolymer to improve efficiency even more.

The work started with the bacteria Bacillus licheniformis, which lives in soil. It has a natural ability to make γ-polyglutamic acid (γ-PGA), a useful polypeptide. They then added cyanobacteria to fix carbon in the air and to use it via photosynthesis to produce a carbohydrate. Next, they added Rhodopseudomonas palustris—bacteria that can convert nitrogen in the air into ammonium.

The result was a mixture of bacteria that together could produce γ-PGA much more efficiently than any known natural method alone, using only solar power, airborne carbon dioxide and nitrogen. Still, the researchers knew the process could be improved. They added a conductive copolymer that allowed the mix of bacteria to form a network of sorts, which made the process of producing γ-PGA both more stable and more efficient.

The process produced an increase in yield by approximately 104% over other natural methods. It also improved photosynthetic efficiency from 0.71 to 1.43%. The team also tweaked the system to make it produce bacitracin A and found it increased yields over other natural methods by approximately 77%. The research group notes that the process is also low-cost and easily scaled up to manufacturing standards. They conclude that their process also serves as a proof of concept, opening the door to the development of similar processes using different ingredients to make different end products.

More information: Wen Yu et al, Solar-powered multi-organism symbiont mimic system for beyond natural synthesis of polypeptides from CO 2 and N 2, Science Advances (2023). DOI: 10.1126/sciadv.adf6772

Journal information: Science Advances

© 2023 Science X Network