This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

UV-sensing wearables project uses new 'switchable dye' tech

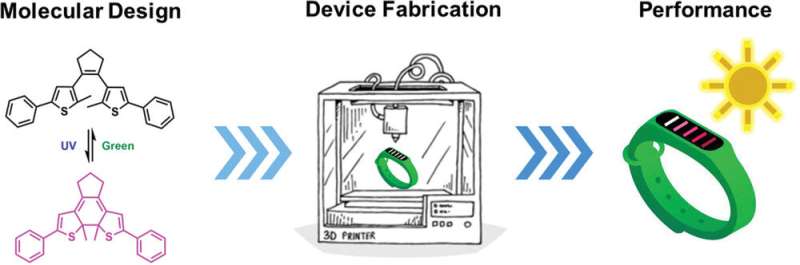

Science and design researchers at QUT have joined forces to develop reusable, color-changing prototypes of jewelry and accessories that use new switchable dye technology to warn people when they've had too much sun.

The devices change from colorless to pink after UV exposure—but can then be reset by putting them in LED (green) light.

Prototypes of the fashion-friendly wearable sensors have been 3D printed out of photopolymer resin, and are currently being trialed by young Australians (aged 18 to 30) as part of a user study.

QUT chemist Dr. Nathan Boase (School of Chemistry and Physics/QUT Centre for Materials Science) and design researchers Dr. Heather McKinnon and Dr. Levi Swann (both School of Design) developed the sensor devices.

Their project aims to eventually—with the help of an industry partner—make fashionable, wearable sensors that change color to tell people their UV risk, and be used over and over again.

Advanced Materials Technologies has published a paper on the switchable dye technology that was authored by the trio and Centre for Materials Science researcher Dr. Sandra Wiedbrauk.

Dr. Boase said there were already stickers on the market that change color, but were single use only.

"Stickers are great for kids, but most adults aren't going to wear them," he said.

"So, instead, we are making 3D printed jewelry and accessories that are appealing to all age groups to use and wear—and, importantly, that can be re-set and re-used to minimize waste."

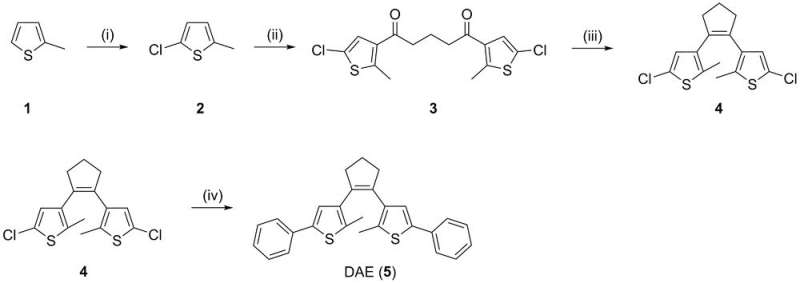

Dr. Wiedbrauk said the most challenging part of the project was developing the switchable dye.

"It's not hard to make something that will change color after prolonged UV exposure … the tricky part is being able to reverse the color change back again for reuse," she said.

"Our switchable dye changes from colorless to pink when exposed to UV light, but can then switch back. We've picked a molecule that no-one seems to have worked with before."

Dr. Boase said the research was the first reported example of an unpowered material that could be reset and reused, providing a more sustainable solution for the market.

"These materials are a platform technology that can be integrated with a range of fabrication techniques and wearables," he said.

"They are unpowered and do not require digital technology to function, but there is potential to integrate with smart phone technology for tracking exposure."

"At this stage the technology is highly sensitive and rapid, and we are working on tuning the sensitivity to provide an estimation of exposure over time."

Dr. McKinnon and Dr. Swann are focused on the design challenge of coming up with product prototypes that can embrace the technology—and that people will want to wear and use.

Dr. McKinnon is an interaction design lecturer and researcher and Dr. Swann is an industrial design lecturer and researcher. Both are also members of the QUT Design Lab.

"Most of our designs resemble jewelry—things that people already use or are easy to incorporate into daily routines … earrings, bracelets, clips to go on bags and beads that can be used in other accessories," Dr. McKinnon said.

"Fitting the designs into everyday life is really important. When we spoke with people about sun safety, they often didn't apply many strategies to protect from the sun in everyday routine and leisure tasks, such as commuting to work and hanging out with friends.

"Accessories like rings, necklaces, and earrings are great for these types of activities as they don't look out of place. Other objects we have designed, such as clips and bracelets, work really well in more active contexts such as exercise and sport. So, there is something for everyone."

Dr. Swann said the compatibility of the switchable dye with 3D printing also had a huge advantage for the project.

"It has effectively allowed us to design and print UV sensors of any shape and style," he said.

"We can then test these different styles to see which one's function best for people and which styles they prefer."

"3D printing also opens the possibility for customizable designs. Imagine if people could create their own or modify existing designs to suit their preferences. This could help build attachment to the accessories and improve their efficacy for encouraging UV protection behaviors."

The research team is also looking for partners who may be interested in helping to manufacture further prototypes or exploring other potential applications of the technology.

More information: Sandra Wiedbrauk et al, Diarylethene Photoswitches and 3D Printing to Fabricate Rewearable Colorimetric UV Sensors for Sun Protection, Advanced Materials Technologies (2023). DOI: 10.1002/admt.202201918

Journal information: Advanced Materials Technologies

Provided by Queensland University of Technology