This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Scientists reveal the mechanism of temperature-dependent structure evolution during electrocatalyst formation

Recently, a research team led by Prof. Liang Haiwei from University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS) studied the structure evolution of intermetallic compounds, a fuel cell electrocatalyst, under high temperature using in-situ high-temperature X-ray diffraction (HT-XRD). They uncovered the phase-transition-temperature-dependent evolution process of the structure. The research was published in Nature Communications.

Previously, Liang's team developed sulfur-anchoring and small-molecule-assisted methods for the general synthesis of Pt-IMCs. However, it was confusing that the lowest temperatures required to obtain the IMCs structure commonly exceeded those of the phase transition temperatures of corresponding alloys, which seemed to contradict common sense idea that only below phase transition temperatures are the ordered alloy phases thermodynamically stable.

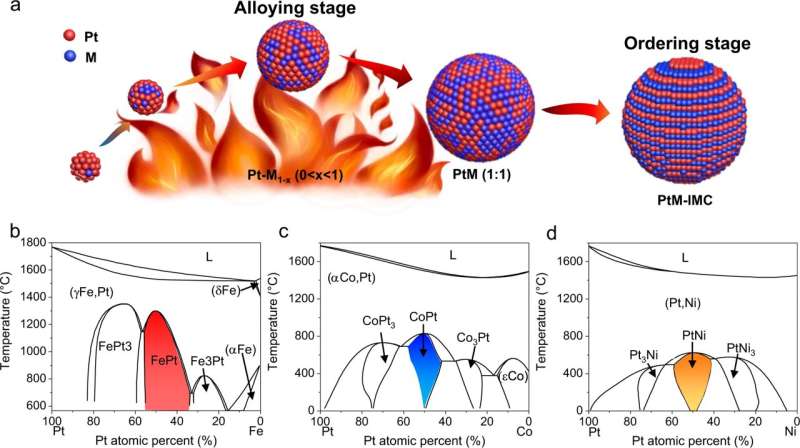

In this research, Liang's group conducted in-situ HT-XRD studies and characterized three types of structure evolution during annealing process: PtFe, PtCo and PtNi. The alloying and ordering are simultaneous for PtFe, while alloying and ordering occurred separately during the heating and cooling stages for PtCo. As for PtNi type, the ordering process was absent.

Researchers then divided the process into two general stages for the three types. The alloying stage helps reach the element ratio, where a high temperature is favored. The ordering stage, however, was marked by phase transition, where a lower temperature is preferred.

According to this guideline, they separately optimized alloying and ordering process and yielded all three types with the tested activity superior to commercialized Pt/C catalyst, among which PtFe stood out for its high capability and durability.

This work highlights the importance of understanding the alloying/ordering stages. It provides a guideline for maximizing the ordering degree of supported intermetallic catalysts with acceptable particle sizes for practical fuel cells.

More information: Wei-Jie Zeng et al, Phase diagrams guide synthesis of highly ordered intermetallic electrocatalysts: separating alloying and ordering stages, Nature Communications (2022). DOI: 10.1038/s41467-022-35457-1

Journal information: Nature Communications

Provided by University of Science and Technology of China