This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

written by researcher(s)

proofread

Foams used in car seats and mattresses are hard to recycle—a new plant-based version avoids polyurethane's health risks

A new plant-based substitute for polyurethane foam eliminates the health risk of the material, commonly found in insulation, car seats and other types of cushioning, and it's more environmentally sustainable, our new research shows.

Polyurethane foams are all around you, anywhere a lightweight material is needed for cushioning or structural support. But they're typically made using chemicals that are suspected carcinogens.

Polyurethanes are typically produced in a very fast reaction between two chemicals made by the petrochemical industry: polyols and isocyanates. While much work has gone into finding replacements for the polyol component of polyurethane foams, the isocyanate component has largely remained, despite its consequences for human health. Bio-based foams can avoid that component.

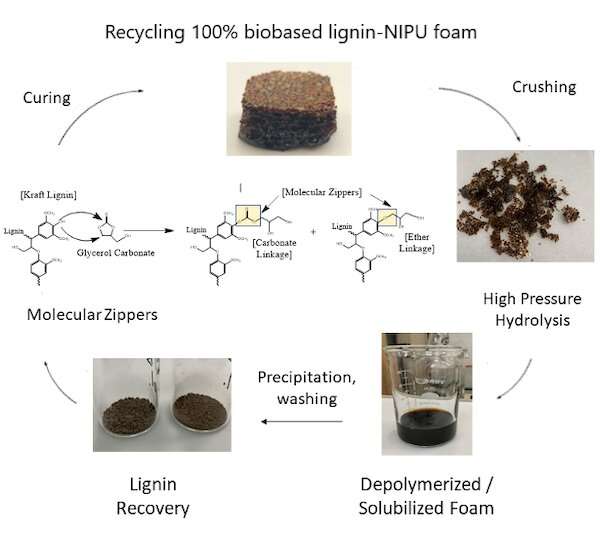

We created a durable bio-based foam using lignin, a byproduct of the paper pulping industry, and a vegetable oil-based curing agent that introduces flexibility and toughness to the final material.

At the heart of the innovation is the ability to create a system that "gels," both in the sense that the materials are compatible with one another and that they physically create a gel quickly so that the addition of a foaming agent can create the lightweight structure associated with polyurethane foams.

Lignin is a difficult material to convert into a usable chemical, given its complicated and heterogeneous structure. We used this structure to create a network of bonds that enabled what we believe is the world's first lignin-based nonisocyanate foam.

The foam can also be recycled because it has bonds that can unzip the chemical network after it has formed. The main components used to produce the foam can then be extracted and used again.

Why it matters

Polyurethane foams are the world's sixth-most-produced plastic yet among the least recycled materials. They are also designed for durability, meaning they will remain in the environment for several generations.

They contribute to the plastic waste problem for the world's oceans, land and air, and to human health problems. Today, plastics can be found in virtually every creature in the terrestrial ecosystem. And since most plastics are made from petroleum products, they're connected to fossil fuel extraction, which contributes to climate change.

The fully bio-based origin of our foams addresses the issue of carbon neutrality, and the chemical recycling capability ensures that waste plastic has a value attached to it so it is less likely to be thrown away. Ensuring waste has value is a hallmark of the circular approach to manufacturing—attaching a monetary value to things tends to decrease the amount that is discarded.

We hope the nature of these foams inspires others to design plastics with the full life cycle in mind. Just as plastics need to be designed according to properties of their initial application, they also need to be designed to avoid the final destination of 90% of plastic waste: landfills and the environment.

What's next

Our initial versions of bio-based foams produce a rigid material suitable for use in foam-core boards used in construction or for insulation in refrigerators. We have also created a lightweight and flexible version that can be used for cushioning and packaging applications. Initial testing of these materials showed good durability in wet conditions, increasing their chance of gaining commercial adoption.

Polyurethane foams are used so extensively because of their versatility. The formulation that we initially discovered is being translated to create a library of precursors that can be mixed to produce the desired properties, like strength and washability, in each application.

More information: James Sternberg et al, Chemical recycling of a lignin-based non-isocyanate polyurethane foam, Nature Sustainability (2023). DOI: 10.1038/s41893-022-01022-3

Journal information: Nature Sustainability

Provided by The Conversation

This article is republished from The Conversation under a Creative Commons license. Read the original article.![]()