Electrokinetic mining technology for recovering rare earth elements from weathering crusts

Rare earth elements (REEs), especially heavy REEs (HREEs), are important in modern industry. However, the conventional mining technique applies excessive usage of ammonium-salt-based leaching agents to recover HREEs from ion-adsorption rare earth deposits (IADs), which exhibits low efficiency and devastating environmental impact on the local ecosystem.

Thus, it's necessary to shift from the traditional "mountain scraping" type of mining to a new generation of green HREE mining.

Recently, a research team led by Prof. He Hongping from the Guangzhou Institute of Geochemistry of the Chinese Academy of Sciences has developed a new technique, electrokinetic mining (EKM), for the green and efficient recovery of REEs from weathering crusts.

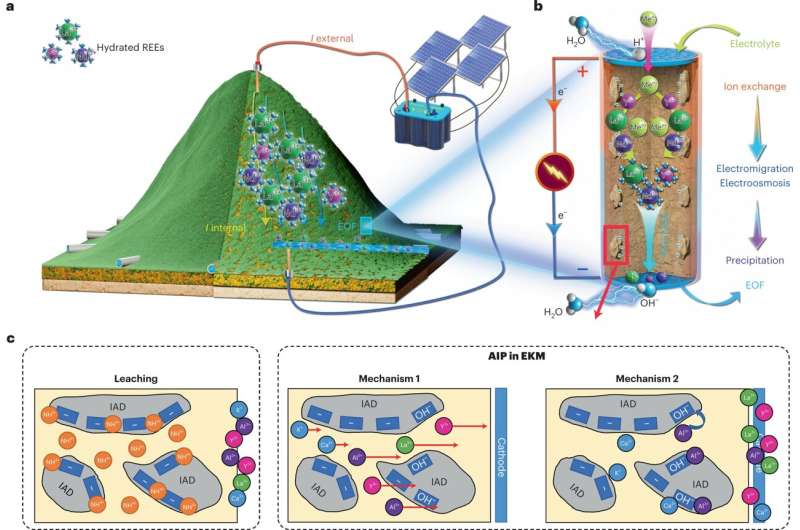

The technique exerts a voltage on the top and bottom of the IAD, which generates an electric field to accelerate REE and water migration toward the cathode.

Compared with conventional techniques, EKM achieves ~90% recovery efficiency, ~80% decrease in leaching agent usage, and ~70% reduction in metallic impurities in the obtained REEs.

The study was published in Nature Sustainability on Oct. 31.

To evaluate the feasibility of EKM for REE recovery, Prof. He's lab first carried out bench-scale experiments in a homemade prototype with a simulated IAD. Results suggested that the REE recovery efficiency achieved by the EKM technique was 2.6 times higher than that achieved by the ammonium leaching technique.

Then, they further carried out scaled-up experiments at the kilogram scale (20 kg) in a larger EKM setup. The results were consistent with bench-scale experiments, i.e., the EKM technique can achieve higher recovery efficiency and requires less treatment time.

Based on the successful bench-scale and scaled-up experiments, they applied the EKM technique to an actual IAD (~14 t-scale) via an on-site field experiment. Results suggested that the REE recovery efficiency achieved higher than 90% in 264 hours.

The researchers further explored mechanisms underlying the high REE recovery efficiency of the EKM. "The applied electric field that accelerates REEs and water migration unidirectionally towards the designed place via electromigration and electroosmosis is the key for enhancing REE recovery efficiency," said Prof. He.

Apart from the sustainability and high recovery efficiency, the EKM shows selectivity for REEs as compared with other metallic impurities (Al3+, Ca2+ Na+, and K+), i.e., the collected metallic impurities are decreased by using the EKM technique. "We identified an autonomous impurity purification mechanism during the electrokinetic process, which is based on velocity and reactivity diversity between REE and other active metal ions," said Prof. He.

More information: Gaofeng Wang et al, A green and efficient technology to recover rare earth elements from weathering crusts, Nature Sustainability (2022). DOI: 10.1038/s41893-022-00989-3

Journal information: Nature Sustainability

Provided by Chinese Academy of Sciences