Tailoring the particle sizes of Pt₅Ce alloy nanoparticles for the oxygen reduction reaction

This study was led by Dr. Yang Hu (Institute of Department of Energy Conversion and Storage, the Technical University of Denmark) and Dr. Qing-Feng Li (Institute of Department of Energy Conversion and Storage, Technical University of Denmark).

Pt-rare earth metal (RE) alloys are a family of catalysts with exceptional performance toward the oxygen reduction reaction (ORR) in acidic media. For the extended surface of bulk polycrystalline Pt5RE electrodes, the reported specific activities are in the range of 7–11 mA cm−2 at 0.9 V (vs. RHE) tested in 0.1 M HClO4 solution, which is 3.5–5.5 times higher than that for the polycrystalline Pt surface.

Two Pt-RE alloys in the form of nanoparticles with uniform sizes, namely PtxY and PtxGd (x indicates varying stoichiometry or poorly defined alloy structure), have been prepared from cluster sources using a gas-aggregation technique. Their specific activities approached 14 mA cm−2, and the mass activities reached 4 A mgPt−1, which are among the highest reported values.

After the accelerated stress test of 10,000 potential cycles between 0.6 and 1.0 V in O2-saturated 0.1 M HClO4, the PtxGd alloy particles retained the mass activity of about 2.8 mA cmPt−1, still 2.8 times more active than the pure Pt counterpart.

However, translating these promising results from bulk electrodes and model particles to a real-world catalyst has yet to be achieved, which has attracted extensive research efforts in the last decade. They aim to synthesize Pt-RE alloy catalysts on a sufficiently large scale and to verify their excellent performance in proton-exchange membrane (PEM) fuel cells and have made significant progress.

Recently, Hu's group developed a universal, scalable chemical approach to synthesize carbon-supported Pt-RE alloy catalysts. The key synthesis process is to heat a mixture of solid-state precursors in a reductive atmosphere. A series of Pt-RE alloy catalysts, such as Pt2Gd, Pt3Y, and Pt5La, have been synthesized using the method. A production scale of up to 10 g per batch has been achieved.

The size of a Pt-RE alloy particles significantly affects both their activity and stability toward the ORR. Previous studies on the model PtxY and PtxGd particles prepared from the cluster source indicated that the optimum particle sizes lay in the range of around 6–9 nm, larger than that (i.e., 3 nm) for the pure Pt nanoparticles. The different optimum sizes originate from the unique structural and chemical properties of the Pt-RE alloy particles.

Rare earth metal ions have very low standard reduction potentials, e.g., –2.372 V for Y/Y3+. Once in contact with an acidic medium, RE atoms are prone to be leached out from the surface region of the alloy particles to form a Pt overlayer, which is compressively strained due to the smaller Pt–Pt distance in the core of the alloy particle.

This strain effect causes the slightly weakened binding energy of HO* on the Pt overlayer and thus increases its activity toward the ORR. The extent of this strain effect is highly dependent on the size of the alloy core. The smaller the particle size, the weaker the effect. Besides, their previous studies showed that Pt-RE alloy particles smaller than 3 nm lost almost all the RE atoms after the treatment in an acidic solution.

Thus, to obtain both the good catalytic activity and stability, Pt-RE alloy particles need to be sufficiently large, optimally above 6 nm. However, big particles inevitably have small specific surface areas and thus a low utilization of the Pt atoms. As a result, an optimum size range of 6–9 nm has been suggested for Pt-RE alloy particles for the ORR.

In this work, Hu and his co-workers attempt to synthesize Pt-RE alloy catalysts with the suggested ideal structures, i.e., an intermetallic Pt5RE phase with the particle size of 6–9 nm. Pt5Ce was chosen as the target alloy phase, because it is one of the most stable Pt-RE alloy structures reported for the ORR, and Ce is one of the most abundant and cheapest RE metals.

Stability and cost are the two crucial factors in the industrial application of the catalyst in PEM fuel cells. They first tried different synthesis conditions and successfully prepared a series of catalysts with a single Pt5Ce phase. Efforts were then made to tailor the sizes of the Pt5Ce particles, which turned out to be the major challenge of this study.

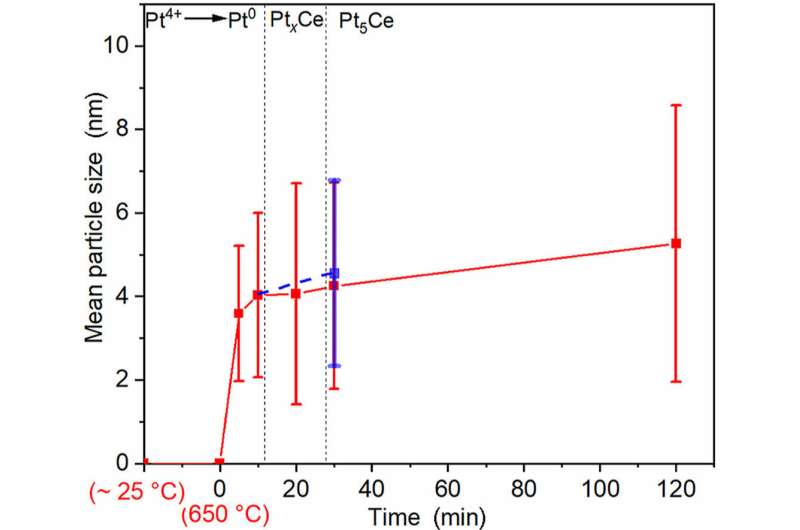

To accomplish this task, they investigated the growth pattern of the Pt5Ce particles during the whole synthesis process. On that basis, they studied the effect of two synthesis parameters on the particle-growth process. Based on the obtained understanding, they have managed to synthesize a Pt5Ce/C sample with the mean particle size of 5.2 nm and a standard deviation of 1.3 nm, which shows promising ORR performance.

The research was published in Advanced Sensor and Energy Materials.

More information: Quan Zhou et al, Tailoring the particle sizes of Pt5Ce alloy nanoparticles for the oxygen reduction reaction, Advanced Sensor and Energy Materials (2022). DOI: 10.1016/j.asems.2022.100025

Provided by Beijing Zhongke Journal Publising Co. Ltd.