Toward 4D printing with structural colors

The colors in the world around us are produced through either absorption of light by molecules (pigmentary colors) or scattering of light by nanostructures (structural colors). Nature provides many spectacular examples of structural colors—the bright colors of some butterflies, beetles, fish or birds (think peacocks) are due to nanostructures that cause the reflected light waves to overlap. Structural coloration occurs on surfaces with a nanostructure with dimensions similar to those of the wavelength of the incident light (typically below a micron). These ordered nanostructures are known as photonic crystals.

Stimuli-responsive colors are a unique characteristic of certain animals, evolved as either a method to hide from enemies and prey or to communicate their presence to rivals or mates. Chameleons, for instance, have the remarkable ability to exhibit complex and rapid color changes. Researchers found out that the color changes take place via the active tuning of a lattice of nanocrystals present in a superficial layer of dermal cells called iridophores. Other structural colors in nature have been found to be responsive to chemicals or to humidity.

From a material science perspective, the solutions developed by nature to achieve these effects have been a source of inspiration to scientists for decades. A recent example is 3D printing with stimuli-responsive materials, called 4D printing. 4D printing enables 3D printed structures to change its configurations over time and is used in a wide variety of fields such as soft robotics, flexible electronics, and medical devices.

Extending 4D printing to structurally colored inks has been the goal of the Stimuli-responsive Functional Materials & Devices group at Eindhoven University of Technology. Seeing the lack of a visibly colored 4D materials, the team set out to design one. As a result, they report in Advanced Functional Materials ("Direct Ink Writing of 4D Structural Colors") the development of a water-responsive cholesteric liquid crystal ink and the accompanying direct ink writing (DIW) procedure. As the researchers demonstrate in their paper, after 3D printing, the humidity-sensitive cholesteric liquid crystal oligomer ink forms a cholesteric phase with visible, colored reflection, and after crosslinking and activation, reversibly changes volume and reflected color based on hydration state.

"This is the first demonstration of a humidity-responsive color changing ink for extrusion 3D printing," Michael G. Debije, an Assistant Professor at TU Eindhoven, tells Nanowerk. "We can now produce computer-aided designs of sensing devices with a marked visual signal—a dramatic change of reflection color—towards the user."

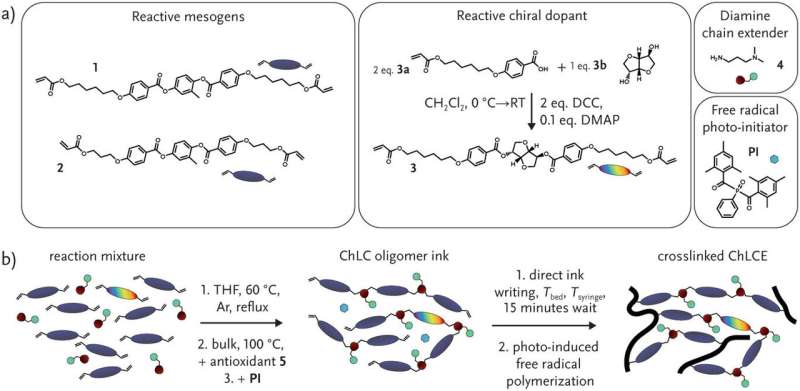

"We designed a special photonic ink for 3D printing from the ground up, starting with careful selection of the molecular building blocks that give us the water-responsivity and colored appearance," explains Jeroen Sol , the paper's first author. "The color comes from what is called a 'cholesteric liquid crystal,' a specific molecular stacking order that interact selectively with specific colors of visible light."

In previous work ("Anisotropic Iridescence and Polarization Patterns in a Direct Ink Written Chiral Photonic Polymer"), the researchers already demonstrated the possibility of printing cholesteric colored objects using microextrusion 3D printing. In this present work, they have added a function long known from liquid crystalline polymers: an autonomous stimulus-response. "We envision that this work will form the basis for 3D printed optical sensing devices, but will also serve as a basis for the development of other responsive 3D printing inks," Sol notes.

The team used two devices to highlight the potential of DIW-responsive cholesteric inks: a 4D-printed color changing element on 3D-printed objects, and a fully 4D-printed, shape changing, structurally colored object.

As has been demonstrated for photonic polymer materials in the past, the extent of its water-response can be typically programmed using other chemical species that influence the degree of polarity. These can be ions, or small bioactive molecules, for instance. As this work demonstrates, it might be possible in the future to design 3D printable, battery-free sensors that target important biomarkers, or imbue sensitivity to heavy metal ions that contaminate water sources.

For now, the team is working on designing 3D printing inks with other types of stimuli-responses, such as response to changing light conditions, and eventually the integration of multiple different 4D inks into single devices that become multi-functional. "Ideally, by including responsive elements in these polymers, we can create materials that can both sense and respond to their environment, perhaps even allowing communication between individual devices as well to generate a level of autonomy for a collection of individual units," Debije concludes.

More information: Jeroen A. H. P. Sol et al, Direct Ink Writing of 4D Structural Colors, Advanced Functional Materials (2022). DOI: 10.1002/adfm.202201766

Provided by Eindhoven University of Technology