May 31, 2022 feature

Microfluidics-assisted synthesis of stimuli-responsive chitosan microgels for drug delivery applications

Droplet microfluidics provide a robust platform to synthesize and functionalize micro- and nanoparticles in a range of applications, including drug delivery, screening, lab-on-a-chip and organ-on-a-chip applications, across chemical and biomedical engineering. Chitosan is a biomaterial suited for diverse biomedical applications, including antibacterial bioactivities with immune-enhancing and anticancer properties. In a new report now published in Scientific Reports, Omid Sartipzadeh and an interdisciplinary research team in medical nanotechnology, biomaterials and tissue engineering, in Tehran, Iran, described the role of chitosan droplets in a microfluidic chip. The outcomes indicated how different sizes and geometries of the chitosan droplets could be established by varying the parameters for several purposes including drug delivery, tissue engineering and cell encapsulation. The team conducted an experimental study that agreed with the simulation outcomes to confirm the results.

Tissue engineering and microfluidics

Monodisperse micro and nanoparticles have attracted great attention across lab-on-a-chip instruments, and biosensors for a range of applications in tissue engineering. Materials scientists and bioengineers have made many attempts to generate uniform micro and nano-particles on demand. However, the interfacial tensions between phases has made it difficult to provide suitable micro and nanoparticles with high quality. Since typical techniques are costly, complex and time-consuming, researchers try to generate monodisperse micro and nanoparticles with on-demand morphology, shapes, and sizes.

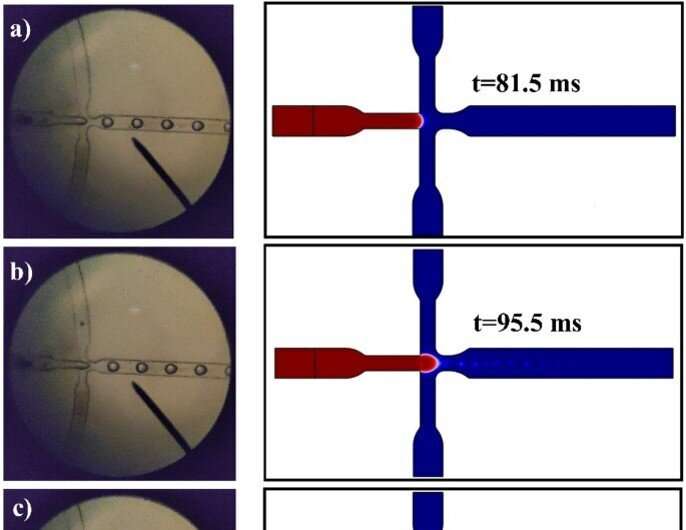

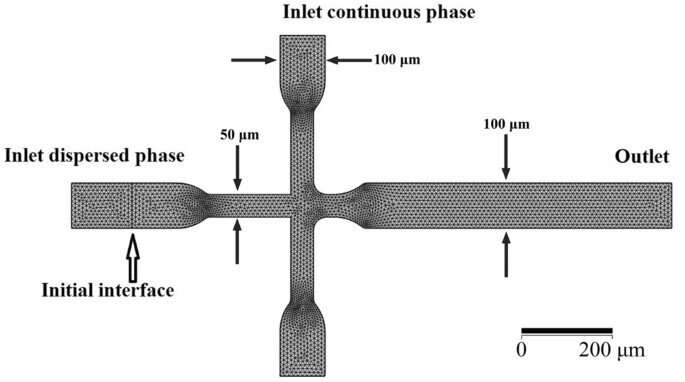

In this work, Sartipzadeh et al investigated the microfluidics droplet generation rates, including flow velocity via COMSOL Multiphysics simulator software to develop practical microfluidic chips for chitosan-oil-chitosan double emulsions. They first experimented with a model of computational fluid dynamics to understand the configuration and features of droplets to create a flow-focused microchannel. Using the simulations, they obtained an approach to achieve greater understanding of the complex on-chip process. The outcomes allowed the team to combine two immiscible fluids and their velocity to examine droplet formation, droplet diameter and their rate of generation.

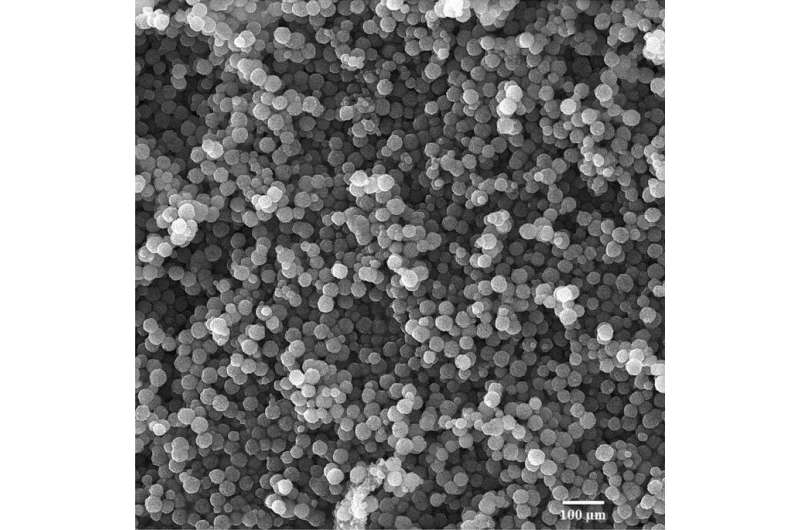

Sartipzadeh et al developed the experimental methods in view of the outcomes of the simulation. They investigated the physical and chemical properties of chitosan and doxorubicin; a type of anthracycline/chemotherapy drug, relative to droplet size and rate of droplet creation. The team determined the pattern and velocity of the components using a microfluidics flow-focusing device (MFFD) to determine droplet size and production rates. Based on the outcomes, the team achieved a comprehensive method to create microfluidic droplets. The MFFDs maintained inlets and outlet conduits to regulate dispersed and immiscible fluid streams colliding with each other at an intersection. The scientists noted how the droplets steered downstream of the main duct based on the pressure gradient and velocity flow of the setup to form four levels of flow. The accompanying snapshots from the simulations illustrated the droplet configuration as a subordinate of time with varying concentrations of chitosan and doxorubicin. Sartipzadeh et al designed and developed the pattern of microfluidic flow-forming on silicon wafer using soft lithography, and cast the mold of the microfluidic flow-focusing device with polydimethylsiloxane. The team bonded the mold of chip patterns onto a slide glass via oxygen plasma, then injected the constituents into the chip using two pumps to examine the mechanisms of combined microgel droplet production.

Dynamics of droplet formation

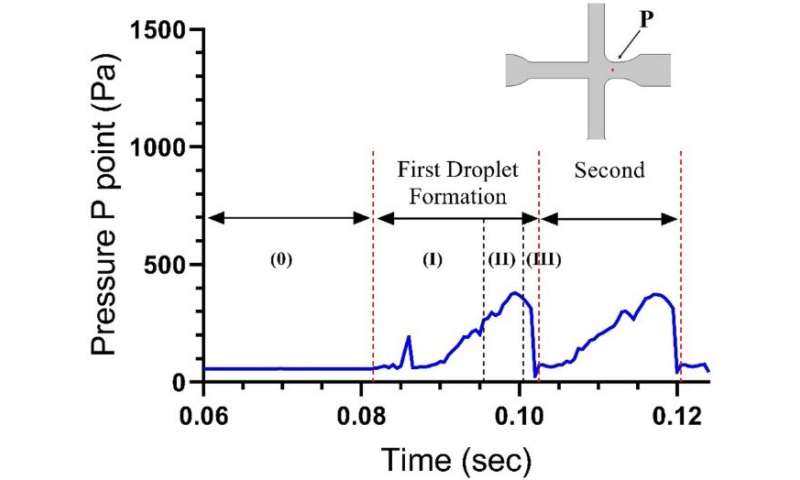

The team explored the dynamics of pressure-directed liquid droplet formation, where they noted a significant increase in the pressure, compared to the pressure before and after the process. The phenomenon relied on the force of pressure, shear stress and surface tension. When the pressure and shear stress were greater than the surface tensile force, the droplet began to thicken and thin. Additionally, the force balance between the parameters of pressure, shear stress and surface tension relied on the physical properties of the solutions of interest. The team explored the concentration of the constituents, relative to the dimensions of the droplet, and indicated an equilibrium between shearing force and interfacial tension. They calculated the liquid flow and its effect on several applications, including lab-on-chip immunoassays, and calculated the size of droplets relative to constituent concentrations, including the frequency of droplet generation and the number of droplets formed in the study. The team credited the outcomes to several parameters of the platform.

Proof-of-concept: Drug release profiles of chemotherapy drug doxorubicin

Sartipzadeh et al then developed a chitosan-doxorubicin mixture with different concentrations of chitosan mixed with a specific amount of the chemotherapy drug doxorubicin, to understand the dependence of droplet diameter on viscosity. The increasing concentration of chitosan led to an increase of its dynamic viscosity to produce droplets of varying diameters. The team next investigated the release of doxorubicin from chitosan in lab, to show how the drug release profile followed a two-way pattern, to highlight the role of chitosan as microcarriers of semi-targeted delivery systems. The scientists examined the drug release profiles from the microcarriers at two different temperatures and pH levels, to highlight the toxicity of encapsulated doxorubicin on cancer cells compared to the free drug. The presence of the carrier made the process of drug release more biocompatible for healthy cells, when compared to the toxicity of the drug in its free form.

-

The procedure of the pressure slope at the P point for the duration of droplet configuration. The P point decides the point situated at the main duct entry. It reverberates the development of the droplet formation process. Three steps formation of droplet: (I) Lag, (II) Filling, and (III) Necking. The CS + DOX velocity is stable at 3.3 mm/s, and the velocity of vegetable oil is equal to 11.1 mm/s. Credit: Scientific Reports (2022). DOI: 10.1038/s41598-022-12031-9 -

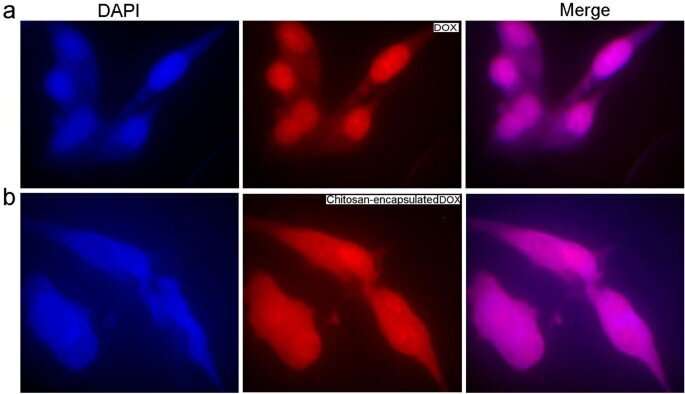

(a) Cellular uptake behavior of DOX by MCF-7 breast cancer cell line. (b) Cellular uptake behavior of CS-DOX by MCF-7 breast cancer cell line. DAPI is used to stain nuclei of cells. Due to its fluorescent nature, DOX causes the cell cytoplasm to turn red on the fluorescent imaging. The images confirm the uptake of the drug by the cells. Credit: Scientific Reports (2022). DOI: 10.1038/s41598-022-12031-9

Outlook

In this way, Omid Sartipzadeh and colleagues developed a computational fluid dynamics model to understand the process of biocompatible chitosan droplet dimensions, and formation in a flow-focused microchannel. The simulation outcomes highlighted an alternate approach to reach the expected experimental results. Based on the studies, the team emphasized the significance of chitosan microparticles for drug delivery applications in biomedicine. The excellent bioactivity, biocompatibility and biodegradability, made the material well suited for various applications in a microfluidic device, including drug screening on lab-on-a-chip platforms and drug delivery within organ-on-a-chip instruments, with 3D cell cultures to assess toxicity of drug candidates. The team conducted a proof-of-concept analysis to address significant challenges in biomedicine and highlighted the role of chitosan droplets as microcarriers for targeted pharmaceutical therapy.

More information: Omid Sartipzadeh et al, Microfluidic-assisted synthesis and modeling of stimuli-responsive monodispersed chitosan microgels for drug delivery applications, Scientific Reports (2022). DOI: 10.1038/s41598-022-12031-9

Elena M. Lucchetta et al, Dynamics of Drosophila embryonic patterning network perturbed in space and time using microfluidics, Nature (2005). DOI: 10.1038/nature03509

Journal information: Scientific Reports , Nature

© 2022 Science X Network