Maize and milk proteins can replace fossil fuels and metals in the production of nanostructured surfaces

New research results from Linnaeus University opens for a future with more sustainably produced nanotechnology, where limited natural resources can be replaced with, among other things, maize and milk proteins.

Nanotechnology can be found almost everywhere in our daily lives, although it is nearly impossible to see. Nanostructures are materials that have been processed at the atomic level to obtain desired material properties. They are used, for instance, in electronics, diagnostics, and as surface treatments for textiles. Nanotechnology has become an indispensable part of modern life.

Given the wide range of areas of use, it becomes important to develop ecologically sustainable production methods and materials in nanotechnology. The production methods used today often require limited natural resources.

"Today, nanostructures are produced from many different types of metals and materials derived from fossil fuels," explains Ian Nicholls, professor of chemistry at Linnaeus University.

Nicholls and his research colleague Subramanian Suriyanarayanan have developed nanostructured surfaces made from natural raw materials found in maize, milk, and crayfish shells. The study, that was published in the journal Scientific Reports, shows that it is possible to create sustainable solutions from biomaterials.

Readily available materials

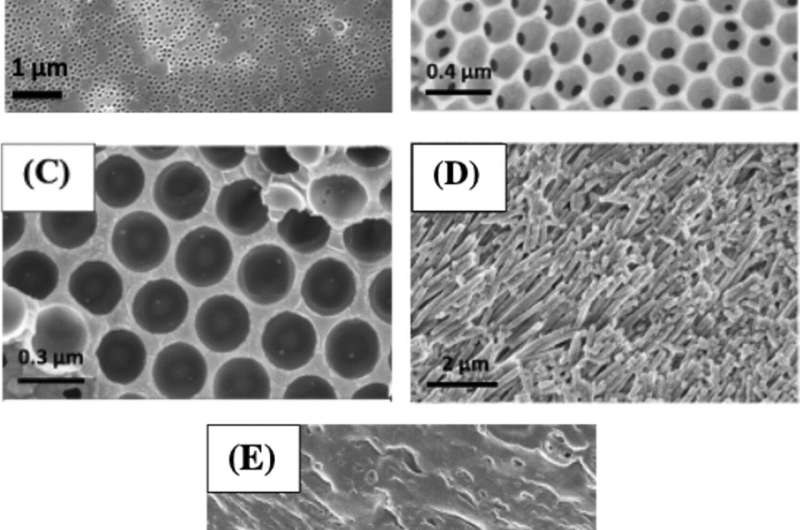

The researchers studied the usability of three renewable and readily available raw materials: zein (a naturally occurring protein found in maize), casein (a type of milk protein), and chitosan (a substance present in, among other things, crayfish shells). The results showed that readily available biomaterials such as these can be used as raw material for nanostructures.

A challenge concerning the use of new biomaterials is how to preserve the properties of the materials over time. In order to come up with an answer to this, the researchers chose to store the nanostructures made of zein, casein, and chitosan for six months and then study how their material properties had changed.

Above all, the maize protein zein demonstrated stable results: After six months, no significant differences could be seen in the quality of the nanostructures, which signals promising properties. However, the results were not as good for the nanostructures that had been produced from casein and chitosan, these did not demonstrate the same good stability.

More research projects underway

Nonetheless, the study points to the possibility to replace fossil fuels and metals in nanotechnology in the future. More research projects are underway to continue to study the possibility to use renewable and readily available raw materials.

"Nanotechnology products are of great benefit to society and it is highly likely that the demand will increase in the future. Therefore, it is very important that these can be produced in a resource-efficient and fossil-free way—which we, through our research, have proved is possible," Nicholls concludes.

Learn more about the research on biosensors and nanostructure from the research project Mindgap

More information: Subramanian Suriyanarayanan et al, Making nanostructured materials from maize, milk and malacostraca, Scientific Reports (2021). DOI: 10.1038/s41598-021-04001-4

Journal information: Scientific Reports

Provided by Linnaeus University