Releasing the heat: A new model to streamline the design of thermally efficient electrical contacts

When we think of modern technology in our daily lives, phones, tablets, and laptops, immediately come to mind. Using these electronic devices for extended periods of time leads to a familiar problem–overheating. As electronics have gotten smaller, getting rid of heat has become more challenging and more necessary.

Everyone has felt their phone grow warm in their palms while playing a game or has needed to shift their computer from lap to table to escape the burning sensation of a browsing session gone too long. Typically, heat is removed through the bottom of the transistors (semiconductor devices) that make up electronic devices; however, research from the College of Engineering at Carnegie Mellon University has shown that the top of the transistor offers an additional heat removal pathway.

Researchers combined analytical approaches and atomistic materials simulations (modeling materials at the atomic level on the computer) to develop a new predictive theory for quantifying heat removal from the top side of a transistor. The work was conducted by Jonathan Malen and Alan McGaughey, professors of mechanical engineering, and Ph.D. student Henry Aller. The findings were published in Physical Review Applied.

"There is the conventional way for removing heat from electronics, which is through the bottom," said McGaughey. "To get it out through the top, you have to go from a semiconductor to a metal. The metal serves a purpose in these devices, which is to provide the electricity; but it also has the potential to help remove the heat. Metals have typically been chosen with the electrical aspects in mind, but not the thermal aspects."

The problem with this approach is that metals are currently preferred for their electrical properties and stability from interfaces with semiconductors that present a large resistance to heat removal. Poor heat removal leads to high operating temperatures and shorter lifespan. The team's research suggests that using two layers of metal, with careful selection of the composition and thickness of the middle layer, can decrease heat-removal resistance.

Their model will help to streamline the development of thermally efficient devices. McGaughey added, "One of the outcomes of this work is that we can now efficiently explore how to choose the metals to put on top of electronics, to augment heat-removal while maintaining normal electrical functionality."

Though the application of their research may be immediately relevant to high-power electronics used for communication technologies, McGaughey expressed that it will have a far-reaching range of utilization.

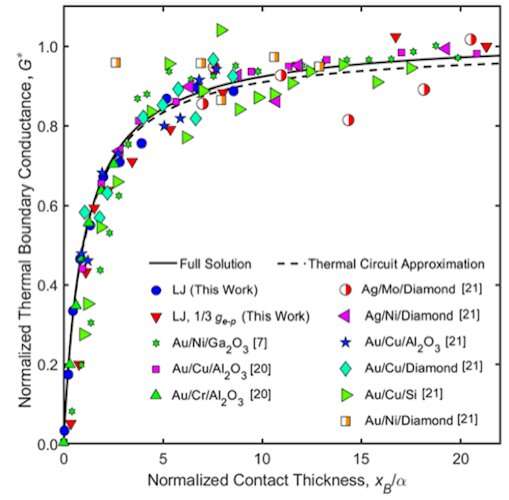

Despite the details being complex, McGaughey believes that the final equation, which mathematically describes the fundamental physics and has been validated against over 100 existing experiments, is easy to use, lending itself to future expansion and research.

More information: Henry T. Aller et al, Universal Model for Predicting the Thermal Boundary Conductance of a Multilayered-Metal–Dielectric Interface, Physical Review Applied (2021). DOI: 10.1103/PhysRevApplied.15.064043