Deficiencies in models used for chemical safety assessment identified

A research project affiliated with the University of Helsinki's Institute for Atmospheric and Earth System Research (INAR) has identified serious deficiencies in the Stoffenmanager and Advanced REACH Tool occupational exposure models used for assessing chemical safety and calls for the discontinuation of their use in statutory chemical safety assessment.

Stoffenmanager and the Advanced REACH Tool (ART) are models recommended by the European Chemicals Agency for the statutory assessment of chemical safety at workplaces. The models are used in legislation to determine the framework for the safe use of chemicals. They are also used for conducting occupational exposure and risk assessment and describing the necessary protective measures in material safety data sheets.

Stoffenmanager offers the facility to register hazardous substances as well as create, export and distribute workplace instruction and safety cards.

The deficiencies in the models recommended by the European Chemicals Agency have a significant effect on chemical safety. Stoffenmanager alone has more than 37,000 users globally, with more than 310,000 risk assessments relating to chemical safety carried out using the model by 2020.

According to a multinational research project headed by researcher Joonas Koivisto from the University of Helsinki, the problems relating to the models are evident in all instances of their use. The models in use have been reported to observe physical principles, such as the law of conservation of mass. However, a theoretical analysis shows that this is not the case.

The study demonstrates the models' uncertainty from three perspectives. Firstly, the models are not based on physics, since the parameters used in the models do not observe causality. For example, in a situation where a local exhaust ventilation is applied, the model should either reduce the general ventilation exhaust volume flow rate or increase the incoming air volume flow rate.

In addition, the parameter values are selected partially subjectively, or as a result of the user's interpretation. According to the third finding, the models are calibrated with subjectively assigned multipliers, which have been determined by mixing various exposure groups, such as the pharmaceutical industry, bakeries and construction sites.

Based on the findings, the modeling approaches do not fulfill the requirements set by the European Chemicals Agency for exposure assessment, which requires objective, or quantitative, exposure values. By combining the uncertainties associated with the models and their interpretive parametrisation, a tiered modeling approach can be used to manipulate exposure values according to the user's wishes.

"There are a lot of uncertainties also in physical models, but in these cases the uncertainties can be determined and modeling accuracy assessed more reliably," says Koivisto.

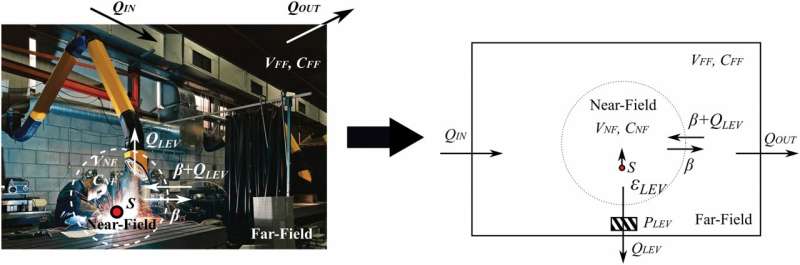

The researchers recommend that the non-physical models be replaced with e.g., a physical two-compartment model. This modeling approach is used to describe higher concentrations close to point sources of emission, taking into account that mass (or amount of the chemical) cannot appear or disappear without a cause.

Koivisto and his colleagues have also carried out a study which describes how the two-compartment model can be used to make well-grounded decisions pertaining to chemical safety, and how this helps determine the preconditions for safe use.

The multi-year project affiliated with the University of Helsinki's Institute for Atmospheric and Earth System Research (INAR) is carried out in cooperation with several research institutes.

More information: Antti Joonas Koivisto et al, Evaluating the Theoretical Background of STOFFENMANAGER® and the Advanced REACH Tool, Annals of Work Exposures and Health (2021). DOI: 10.1093/annweh/wxab057

Provided by University of Helsinki